The energy industry strives to meet the world’s demands for powering everything from electrical appliances to gas-powered vehicles and much more. Producing reliable energy requires high-precision fabrication of components for energy equipment that meets tight tolerances and is capable of withstanding wear and extreme environmental factors.

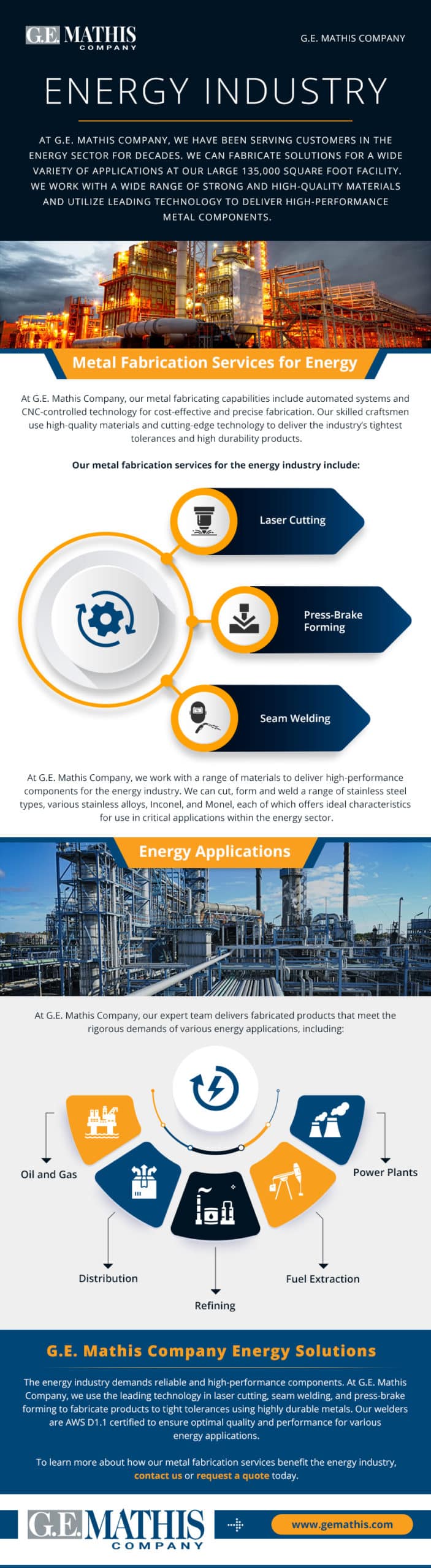

At G.E. Mathis Company, we have been serving customers in the energy sector for decades. We can fabricate solutions for a wide variety of applications at our large 135,000 square foot facility. We work with a wide range of strong and high-quality materials and utilize leading technology to deliver high-performance metal components.

Metal Fabrication Services for Energy

At G.E. Mathis Company, our metal fabricating capabilities include automated systems and CNC-controlled technology for cost-effective and precise fabrication. Our skilled craftsmen use high-quality materials and cutting-edge technology to deliver the industry’s tightest tolerances and high durability products.

Our metal fabrication services for the energy industry include:

- Laser Cutting. Laser cutting is a thermal cutting technique that relies on a highly focused light beam to perform precise and clean cuts. Our laser cutting services accommodate a wide range of materials and thicknesses in production runs from prototype to high-volume orders.

- Press-Brake Forming. Our press-brake forming capabilities allow us to precisely bend and form metal with up to 1000 tons of force. Our equipment can accommodate lengths up to 48-feet and thicknesses up to 2-inches.

- Seam Welding. Using MIG and arc welding techniques, we offer high-precision seam welding services for the energy industry. In addition, G.E. Mathis Company has a Certified Welding Inspector (CWI) on staff. We accommodate a range of materials, and we offer CNC-controlled and fully automated welding for large-scale production runs.

Our expert fabricators work with a range of materials to deliver high-performance components for the energy industry. We can cut, form and weld a range of stainless steel types, various stainless alloys, Inconel, Monel, and Alloy 2205, each of which offers ideal characteristics for use in critical applications within the energy sector.

Energy Applications

At G.E. Mathis Company, our expert team delivers fabricated products that meet the rigorous demands of various energy applications, including:

- Power plants. Power plants require precise and durable fabricated components for power generation equipment such as pressure vessels. We provide high-quality fabricated parts for power plants that comply with strict industry standards.

- Fuel extraction. Well sites and pipelines require high-quality fabricated metal parts for reliable extraction and transport of fuel.

- Refining. Refineries are exposed to corrosive elements, so it is important to have fabricated metal parts that can withstand these conditions. We offer various types and alloys of stainless steel to provide corrosion-resistant components for refining applications.

- Distribution. The distribution of refined products requires corrosion-resistant, strong, and high-quality fabricated metal parts.

- Oil and gas. Oil and gas applications such as extraction, storage, and transportation, require durable, wear-resistant components made from high-quality materials. We can fabricate various high-performance and heavy-duty structural components to suit these needs.

G.E. Mathis Company Energy Solutions

The energy industry demands reliable and high-performance equipment. At G.E. Mathis Company, we use the leading technology in laser cutting, press-brake forming, and welding to fabricate products to tight tolerances using highly durable metals. Our welders are AWS D1.1 certified to ensure optimal quality and performance for various energy applications.

In addition to being an ISO 9001:2015-certified manufacturer, G.E. Mathis Company can provide the following services:

- PPAP (Production Part Approval Process) – All Levels

- FAIR (First Article Inspection Report)

- Capability Studies (Statistical Process Control)

- CMRT (Conflict Minerals Reporting Template)

To learn more about how our metal fabrication services benefit the energy industry, contact us or request a quote today.