Founded in 1905, G.E. Mathis Company is a premier metal fabrication shop and contract manufacturer serving demanding industries worldwide. Dedicated to quality craftsmanship, customer service, and operational integrity, we specialize in long, close-tolerance, and intricate fabrications. Among our turnkey service offerings are our precision laser cutting capabilities for sheet metal, stainless or carbon steel, and more. From prototypes or small orders to high-volume production, our team can assist you with quality services to meet your exact product specifications for diverse and custom laser cutting projects.

Our Premier Laser Cutting Capabilities

With our skilled technicians and advanced laser cutting equipment, we can accommodate various materials, thicknesses, and production volumes. By partnering with G.E. Mathis Company, you’ll be able to take advantage of:

- Large-capacity laser processing systems. Our large-capacity laser systems include a gantry setup that can process 14-foot-by-100-foot sheets and plates with a maximum power capacity of 6,000 watts. We also have a pallet system capable of cutting up to 8-foot-by-20-foot with an 8,000-watt maximum power output.

- Material thickness flexibility. Our 3-axis CO2 flying optic and hybrid laser technologies allow us to create high-quality products from materials with thicknesses ranging from 16-gauge sheets to 1.25-inch-thick plates.

- Scalable production capabilities. We process everything from single prototypes to high-volume runs, providing end-to-end services tailored to your specific laser cutting needs.

- Design versatility. With our precision laser processing technologies and large-capacity systems, we can cut virtually any shape with incredible accuracy. While it would be difficult or expensive to manually cut certain configurations with standard equipment, laser cutting accommodates unique designs and complex, non-circular geometries with precision and ease.

- Comprehensive solutions under one roof. We also provide a range of in-house secondary and finishing services to complement our core metal fabrication capabilities, such as press-brake forming, and welding. We aim to be a one-stop shop, eliminating the hassle of managing multiple vendors for different tasks while decreasing turn times and costs for our customers. We want clients to know that their project is in capable hands from start to finish.

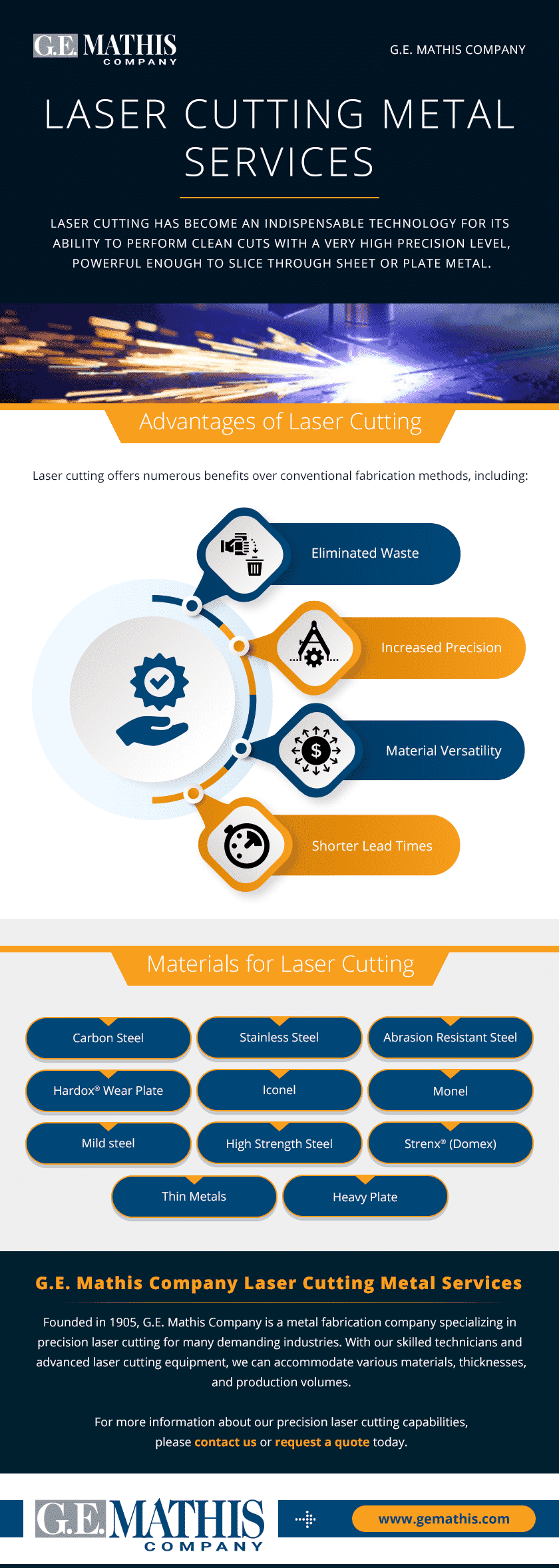

Advantages of Laser Cutting

Eliminated Waste

Laser cutting maximizes material usage, enabling a significant reduction in scrap. Waste reduction is especially beneficial when using expensive materials. Laser cutting is also very energy efficient, consuming substantially less power than other cutting methods.

Increased Precision

Compared with plasma cutting, machining, and other standard fabrication techniques, laser cutting allows for much greater cutting precision. The highly focused beam can cut within very tight tolerances without significantly impacting metal outside the cutting area. Able to accurately achieve virtually any shape or geometry, laser cutting has become a preferred choice for applications in aerospace, defense, microelectronics, and other precision industries.

Material Versatility

Laser cutting is suitable for a wide range of metallic and non-metallic materials and can cut through sheets of varying thicknesses. Manufacturers often prefer waterjet or plasma cutting for very thick material, but laser cutting’s exceptional versatility makes it a valuable modern cutting tool. Laser cutting is also suitable for soft materials that may be damaged by other cutting methods.

Shorter Lead Times

Laser cutting eliminates the need to custom-design or modify specialized tooling for every project. A laser can perform all operations without constantly changing out tooling between tasks, resulting in lower equipment costs and shorter lead times. Without expensive tooling, laser cutting offers a highly cost-effective option, even for small-batch or limited-run projects.

Materials for Laser Cutting

While compatible with virtually any non-reflective material, laser cutting is most commonly used to cut metals. There are many types and grades of metal used in manufacturing, each with its advantages and limitations for laser cutting. The properties and thickness of the material will ultimately dictate the best cutting method. At G.E. Mathis Company, we frequently laser cut the following materials:

- Carbon Steel

- Stainless steel

- Abrasion resistant steel

- Hardox® wear plate

- Inconel

- Monel

- Mild steel

- High strength steel

- Strenx (Domex)

- Thin metals

- Heavy plate

Industries and Applications

A multitude of industries have benefited from G.E. Mathis Company’s laser cutting and laser processing capabilities, including Heavy industry, truck cranes, booms, frame rails and wear parts, among others.

Our precision laser cutting experience spans across the following industries and applications:

- Agriculture

- Aerospace

- Construction / Cranes

- Energy

- Heavy industry

- Mining

- Military and defense

- Trailers / Truck frames

- Original equipment manufacturing (OEM)

- Contract manufacturing

- General industrial

Ready to Discuss Your Project? Contact Us to Experience the G.E. Mathis Company Difference!

Whatever the needs of your application, the team at G.E. Mathis Company is here to help with our versatile metal laser cutting services. From our advanced production facility of 135,000 square feet in Chicago, Illinois, we can handle projects of virtually any size, material, thickness, or order volume.

Our fourth-generation family business also offers laser etching, steel press brake bending and forming, custom welding, and contract manufacturing to ensure that you have access to everything you need under one roof. Contact us today to learn more about our precision laser cutting capabilities, or request a quote to discuss your project.

Our Commitment to Quality

Our team is fully dedicated to ensuring customers receive the highest quality fabricated components for their needs. G.E. Mathis Company is proudly ISO 9001:2015 certified, meaning our quality management system meets all ISO requirements. We work hard to maintain this certification so our customers have peace of mind, knowing they will receive the highest quality products and services from our company. In addition, G.E. Mathis Company can provide the following services:

- PPAP (Production Part Approval Process) – All Levels

- FAIR (First Article Inspection Report)

- Capability Studies (Statistical Process Control)

- CMRT (Conflict Minerals Reporting Template)

Request Quote

Please complete the form below and we will contact you shortly.

Over 100+ Years of Experience

Trained & Certified Expertise

Reliable Customer Service