Metal fabrication services are essential to the production of armored vehicles and machine weaponry in the defense industry. Defense units operate in extreme conditions and require precisely manufactured components to operate safely and effectively.

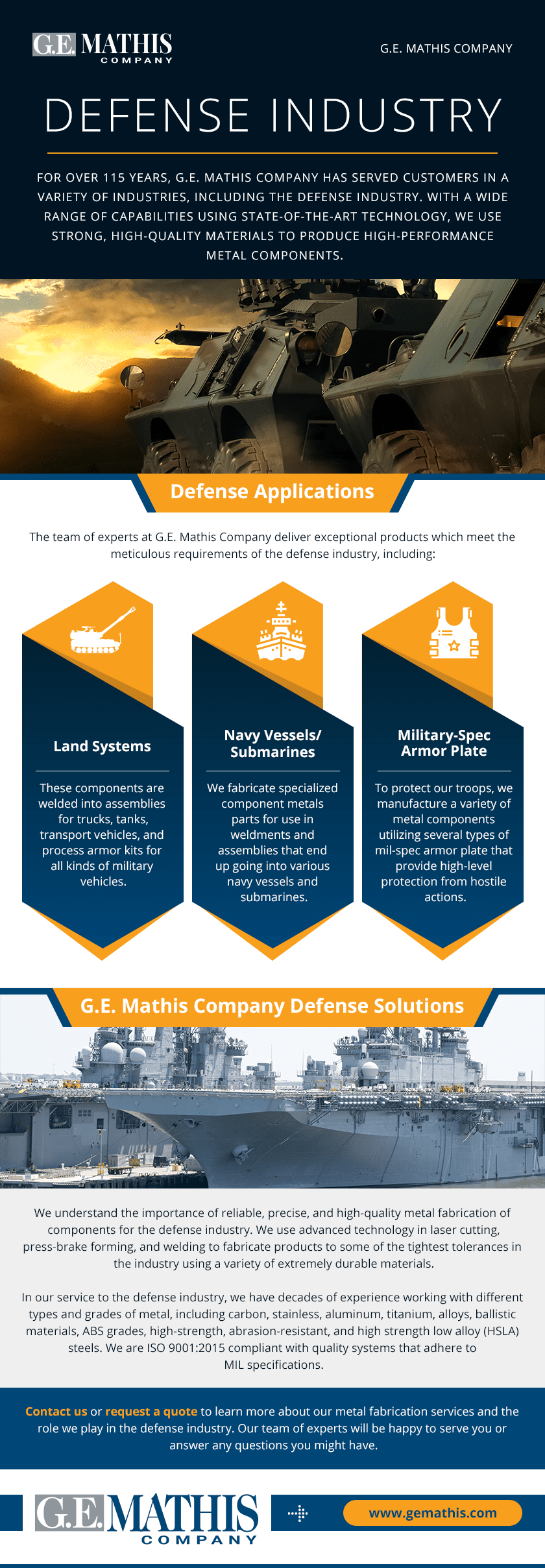

For 119 years, G.E. Mathis Company has served customers in a variety of industries, including the defense industry. With a wide range of capabilities using state-of-the-art technology, we use strong, high-quality materials to produce high-performance metal components.

Metal Fabrication Services for Defense

Metal fabrication refers to the processes raw or semi-finished metal materials undergo to be transformed into finished products. Material selection and design are determining factors of the fabrication method used. Some of the materials manufacturers use in metal fabrication include carbon steel, aluminum, stainless steel, titanium, high-strength steel, abrasion-resistant steel, along with other alloys.

G.E. Mathis Company offers a range of metal fabricating capabilities, including automated systems and CNC-controlled technology. Our skilled craftsmen use high-quality materials and cutting-edge technology to deliver the defense industry’s most precise and durable metal component parts..

G.E. Mathis Company offers the following metal fabrication services for the defense industry:

Laser cutting

Laser cutting is a thermal cutting process that employs a highly focused light beam powerful enough to vaporize the material along a cut path, resulting in a finished product. The resulting component part has clean-cut edges with little to no dross, slag or burrs along the laser-cut ede.This method is ideal for applications that require precise cutouts, high tolerances, and complex geometries.

Press Brake Forming

Our press-brake forming capabilities allow us to precisely bend and form metal with up to 1000 tons of force. Our equipment can accommodate lengths up to 48-feet and thicknesses up to 2-inches.

Welding

High heat and pressure are applied to two or more metal pieces to fuse them together. Our welding capabilities include Metal Inert Gas (MIG) welding, Shielded Metal Arc Welding (SMAW), Flux-Cored Arc Welding (FCAW), and Gas Tungsten Arc Welding (GTAW), among others. In addition, G.E. Mathis Company has a Certified Welding Inspector (CWI) on staff.

Defense Applications

The team of experts at G.E. Mathis Company deliver exceptional products which meet the meticulous requirements of the defense industry, including:

Land Systems

G.E. Mathis Company utilizes advanced technology to manufacture component parts that go into military vehicles. These components are welded into assemblies for trucks, tanks, transport vehicles, and process armor kits for all kinds of military vehicles.

Navy Vessels/Submarines

We fabricate specialized component metals parts for use in weldments and assemblies that end up going into various navy vessels and submarines.

Military-Spec Armor Plate

To protect our troops, we manufacture a variety of metal components utilizing several types of mil-spec armor plate that provide high-level protection from hostile actions.

G.E. Mathis Company Defense Solutions

In our service to the defense industry, we have decades of experience working with different types and grades of metal, including carbon, stainless, aluminum, titanium, alloys, ballistic materials, ABS grades, high-strength, abrasion-resistant, and high strength low alloy (HSLA) steels.

In addition to being an ISO 9001:2015-certified manufacturer, G.E. Mathis Company also provides the following services:

- FAIR (First Article Inspection Report)

- Capability Studies (Statistical Process Control)

- PPAP (Production Part Approval Process) – All Levels

- CMRT (Conflict Minerals Reporting Template

Contact us or request a quote to learn more about our metal fabrication services and the role we play in the defense industry. Our team of experts will be happy to serve you or answer any questions you might have.