The construction and crane industry relies on heavy-duty equipment for excavation, paving, and building. At G.E. Mathis Company, we fabricate high-strength and abrasion-resistant steel component parts for the construction and crane industry. Our capabilities allow us to fabricate components for paving, earth-moving, and lifting equipment to suit the needs of various applications. We deliver a wide range of fabrication services, and we can accommodate quantities from prototype runs, all the way up to blanket orders to fit the needs of contract manufacturers.

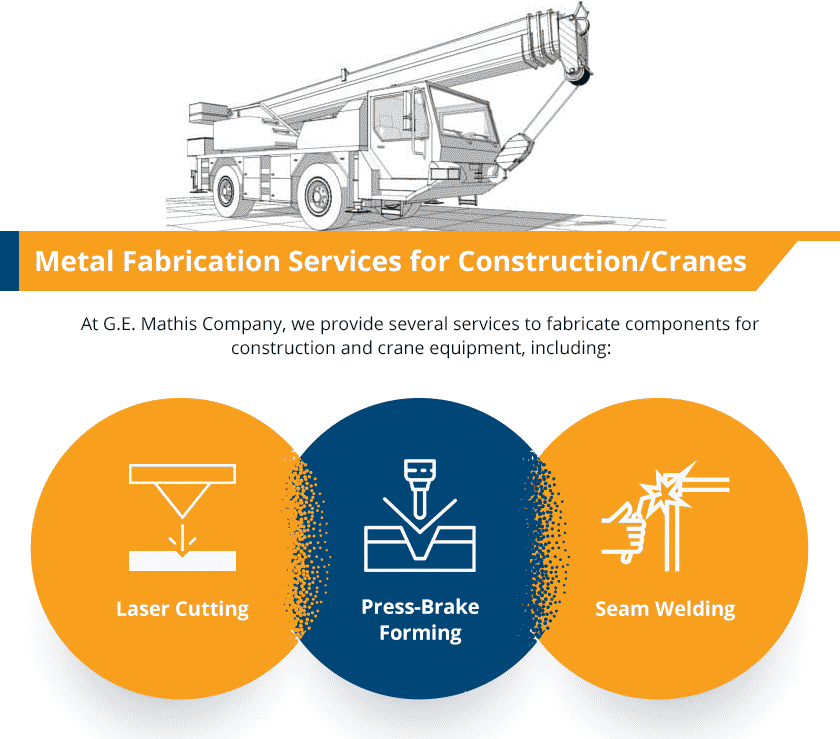

Metal Fabrication Services for Construction/Cranes

At G.E. Mathis Company, we provide several services to fabricate components for construction and crane equipment, including:

Cranes and construction equipment depend on high-quality materials for reliable performance and longevity. We use the following materials in our fabrication processes:

High-strength steels have a high kilopound per square inch (ksi) rating for better durability and longevity. Parts can also be thinner and lighter than conventional steel while offering the same or greater strength.

This type of high-strength steel features 100 ksi minimum yield strength. It has high tensile strength, making it suitable for various construction and crane equipment.

This durable material achieves superior longevity and resistance to wear and abrasion. This makes it an ideal material for paving and excavation equipment.

This grade of steel offers high-strength and corrosion resistance. Crane booms and other construction equipment depend on this durable low-alloy steel.

This high-strength steel from SSAB offers exceptional structural strength and lightweight performance, making it a suitable option for construction and crane components.

This abrasion-resistant steel from SSAB offers abrasion resistance, long lifespan, and excellent performance in wear-prone applications.

Construction Applications

G.E. Mathis Company fabricates components for equipment used in a range of construction and crane applications. For the construction industry, we manufacture components for earth moving equipment such as excavation equipment with abrasion-resistant steels like HARDOX® Wearplate. We also fabricate paving equipment components, which requires exceptional abrasion resistance for mixing and forming cement and other compounds used in construction.

Our 135,000 square foot fabrication facility is ideal for manufacturing large and long component parts for lifting equipment. We fabricate custom crane booms, the portion of the crane or lift equipment that extends to carry the load. Lifting equipment requires high-strength low alloy steel like A656 Grade 80 or STRENX® to lift heavy materials.

G.E. Mathis Company Construction Solutions

The construction industry requires high-strength and abrasion-resistant equipment to increase longevity and deliver heavy-duty performance. G.E. Mathis Company has been delivering high-quality fabrication services, including laser cutting, press-brake forming, and welding for 120 years. We serve the construction and crane industry with components made using high-quality materials and the tightest tolerances in the industry. Our low rejection rates and short lead times help us meet your expectations.

In addition to being an ISO 9001:2015-certified manufacturer, G.E. Mathis Company can provide the following services:

(Production Part Approval Process)

(Statistical Process Control)

(Conflict Minerals Reporting Template)

To learn more about our solutions for the construction and crane industry, contact us or request a quote to speak with our specialists today.