Announcing the Addition of the 8-kW Fiber Optic Laser Cutting System

Leave a CommentAs an industry leader in the fabrication of long, close-tolerance components, G.E. Mathis Company is committed to continuously expanding its service offerings. Most recently, we’ve added an 8-kilowatt fiber-optic laser cutting system—one of the largest pallet-changing laser formats in the industry—to our facility. This new addition allows us to increase the efficiency of our processing operations for materials as large as 100 inches wide by 240 inches long as well as offers several other improvements to our laser processing capabilities.

Features and Capabilities of the 8kW Fiber Optic Laser Cutting System

The integration of the new 8kW laser into our facility has greatly increased and improved our laser processing capabilities. Employing a 3-axis flying optic (or hybrid) positioning system, LoadMaster automatic sheet loading system, and BrightLine Fiber adaptive laser beam in a full enclosure, it accommodates the following project specifications:

- Manufacturing type: prototype, contract manufacturing, and fabrication

- Materials: carbon steel, stainless steel, abrasion-resistant (AR) steel such as HARDOX®, high-strength steel such as STRENX®, aluminum, and other alloys.

- Material thicknesses: up to 1.25 inches for carbon steel and up to 1 inch for stainless steel

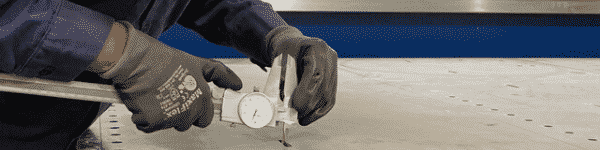

- Tolerances: starting at +/- .015 inches

- Volume: Prototype to production

- Delivery/lead time: 1 to 2 weeks

- Industry standards: 1SO 9001:2015

- File formats: AutoCad, Inventor, PDF, DWG, DXF, STEP

Benefits of the 8-kW Fiber Optic Laser Cutting System

Using the new system for our laser processing operations provides us with a number of benefits, including:

- Broader material capabilities. The laser system allows us to cut a variety of steel and steel alloys in greater thicknesses (up to 1 inch for stainless and 1.25 inch for carbon).

- Higher cut quality. The system’s BrightLine Fiber adaptive beam mode facilitates the production of higher quality cuts in even thick plates, simplifies the removal of individual parts, and reduces the contours created throughout cutting operations.

- Safer and more environmentally sound operations. As the system’s critical components are fully contained within an enclosure, laser processing operations that employ it offer a lower risk to personnel and the surrounding environment.

Industries Served by the 8kW Fiber Optic Laser Cutting System

Equipped with the new system, we are able to provide more advanced laser processing services to the following industries:

- Aerospace

- Agricultural

- Contract manufacturing

- High-quality component manufacturing

- Military

- Construction

- Mining

Laser Processing Solutions From G.E. Mathis Company

At G.E. Mathis Company, we are dedicated to providing high-quality laser processing solutions to our customers. Craig Mathis—President of G.E. Mathis Company—best states how we go about achieving this goal: “We continue to invest in the latest fabrication technology which enables us to deliver value-added products to the industries we serve.” Our current processing equipment includes three different types of lasers (including the 8kW fiber optic laser) and large-capacity gantry-type and pallet-type processing systems, which allow us to cut a wide range of designs and geometries in materials ranging from 16 gauge sheet to 1.25 inch thick plate.

In addition to being an ISO 9001:2015-certified manufacturer, G.E. Mathis Company can provide the following services:

- PPAP (Production Part Approval Process) – All Levels

- FAIR (First Article Inspection Report)

- Capability Studies (Statistical Process Control)

- CMRT (Conflict Minerals Reporting Template)

In addition to our top-of-the-line laser processing services, we also offer secondary and finishing services. As a one-stop shop, we provide faster turnaround and reduced manufacturing costs. For more information on our laser cutting equipment and services, contact us today.