Metal fabrication refers to any of the core processes used to create a finished product from raw or semi-finished metal materials. Most metal fabrication processes begin with stock metal, such as bars, sheets or plates. Specific design factors and material selection will ultimately determine which method to use on any given project. Metal fabrication capabilities allow manufacturers to work with a variety of materials, including:

- Aluminum

- Brass

- Carbon Steel

- Copper

- Iron

- Nickel

- Magnesium

- Stainless Steel

- Tin

- Titanium

Types of Metal Fabrication

Four primary categories of metal fabrication cover the majority of fabricating processes. These include:

1. Cutting

- Precision laser cutting. Laser cutters use a high-powered, focused laser beam to create incredibly precise cuts. We use advanced, 3-axis, CO2 flying optic and hybrid laser cutting equipment capable of precision cuts on materials ranging from 16-gauge up to 1.25″ plate. Our large-capacity gantry laser processing system features a 14 ft. by 100 ft. table and maximum output power of 6,000 watts. Our pallet machine handles width up to 8 ft. and lengths of 20 ft. with output power up to 8,000 watts. These capabilities enable us to cut nearly any geometry within very tight tolerances.

- Precision plasma cutting. Plasma cutting ignites a gas using an electric arc, which heats the gas to plasma temperatures of up to 40,000°F. The resulting plasma jet can cut any electrically conductive metal. At G.E. Mathis Company, we use a high-definition, computer numerical controlled (CNC) plasma cutting machine that can cut parts up to 3.00″ thick. With a 10 ft. by 90 ft. cutting table and 400-amp, 4-axis, dual-head equipment, we offer precision cuts on tough steels, steel alloys, and nearly any other conductive metal.

2. Bending

In this metal forming process, sheet or plate metal is manipulated and bent to a specific angle. A press brake uses a set of top and bottom tooling to apply up to 1,000 tons of pressure to a metal plate, and bends that plate to a certain angle according to the customer drawing.

- Precision forming/bending. G.E. Mathis Company has a fleet of eight hydraulic press brakes — four manual and four CNC-controlled. Our experienced craftsmen are able to produce a wide variety of component parts, including formed angles, bump-formed segments, cone segments, cylinder segments, elbow transitions, square to round transitions and much more from an expansive range of metal materials.

3. Welding

At G.E. Mathis Company, our welding capabilities include the following:

- Shielded Metal Arc Welding (SMAW). Also known as stick welding or arc welding, this manual process produces an electric welding arc via a consumable electrode stick.

- Metal Inert Gas (MIG) Welding. This method uses a continuous solid wire electrode and external supply of gas to shield the metal from the reactive environmental factors.

- Gas Tungsten Arc Welding (GTAW). GTAW welding—also commonly referred to by its most popular form, Tungsten Inert Gas (TIG) welding—uses a non-consumable tungsten electrode protected by an inert gas. This process is complex and requires more training and skill to perform manually, so it is often automated.

- Flux Cored Arc Welding (FCAW). This welding technique is technically similar to the MIG process but instead produces the gas from the core to eliminate the need for an external gas source. FCAW equipment is relatively lightweight, making it portable and convenient, but it doesn’t work with thinner metals.

In addition, G.E. Mathis Company has a Certified Welding Inspector (CWI) on staff.

Please visit our precision welding page for a full list of welding capabilities at G.E. Mathis Company.

Industries Served

Manufacturers in virtually every industry rely on some form of metal fabrication to produce goods. At G.E. Mathis Company, we work with customers across industries such as:

- Aerospace. Our aerospace customers rely on us to produce high-quality components within very tight tolerances.

- Agriculture. We regularly fabricate durable metal components for agricultural machinery, such as tractors, balers, backhoes, and harvesters.

- Construction. We fabricate a variety of structural components, such as support pilings, laser-cut railings, and components for road paving equipment, custom boom tube sections for crane equipment, and more.

- Military and defense. We’ve contributed precision components for defense communication tools, radios, antennas, tanks, transport vehicles, and more.

- Oil and gas. The dedicated craftsmen at G.E. Mathis Company regularly fabricate components that can tolerate the harsh conditions of oil and gas environments, such as those found in fracking equipment.

- Original equipment manufacturers (OEMs). A variety of OEMs rely on us to produce reliable parts for mechanical equipment, including construction machinery, power generators, lighting equipment, and much more.

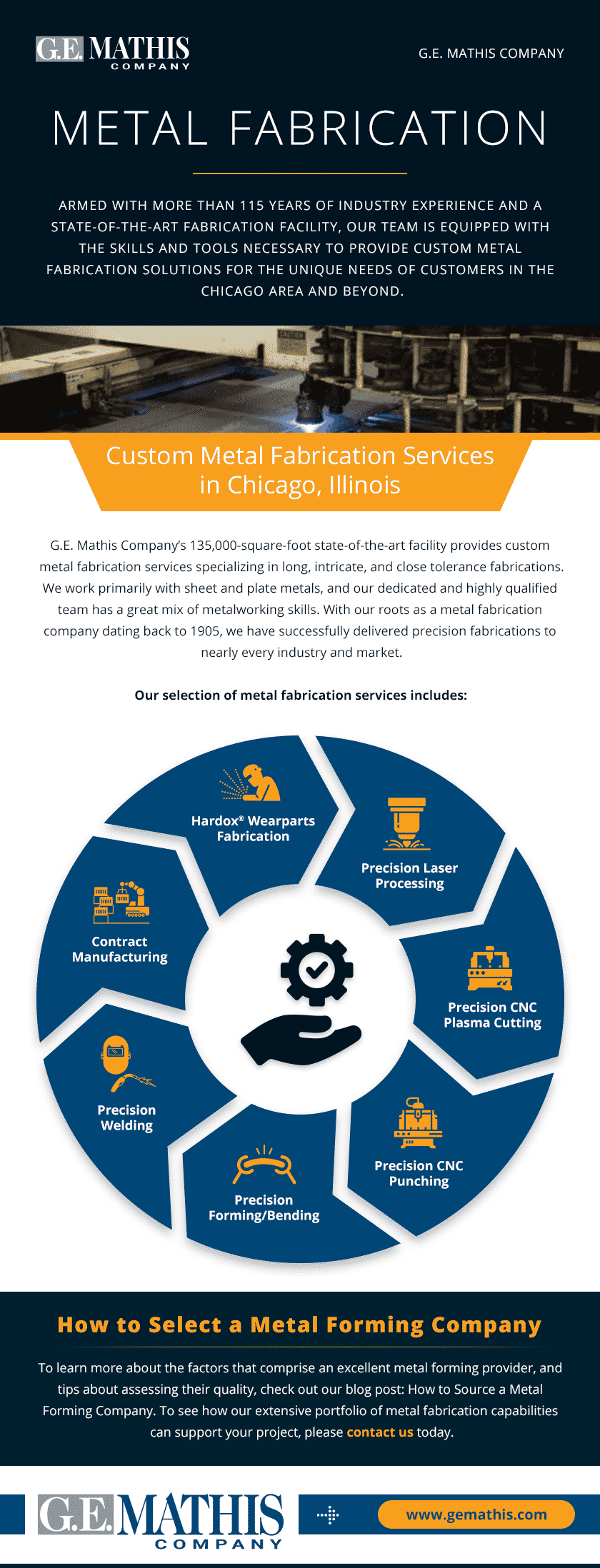

How to Select a Metal Forming Company

To learn more about the factors that comprise an excellent metal forming provider, and tips about assessing their quality, check out our blog post: How to Source a Metal Forming Company. To see how our extensive portfolio of metal fabrication capabilities can support your project, please contact us today.

Request Quote

Please complete the form below and we will contact you shortly.

Over 100+ Years of Experience

Trained & Certified Expertise

Reliable Customer Service