What Is Contract Manufacturing?

What Is Contract Manufacturing?

Contract manufacturing is a form of outsourcing in which a company partners with an expert third-party manufacturer to create part or all of a component or assembly at an agreed-upon price for a set length of time. By allowing companies to transfer portions of their work to a reliable sub-contractor, this type of business relationship reduces the need for the project to be completed in-house, which can mean a significant decrease in labor and equipment costs for the contracting company.

Below, we provide an overview of contract manufacturing, highlighting how it works, what benefits it offers (e.g., increased cost-savings, streamlined operations, and improved productivity), and what types of products it is used to make.

How Does Contract Manufacturing Work?

After reviewing the details of the client’s request, a contract manufacturer creates a quote or estimate based on the labor, materials, and tooling costs necessary for the project. In addition to considering the amount of time and labor that will go into the project, the company provides information for projected tolerances, depending on the component material, overall component size, and required fabrication processes.

Contracting companies often request bids from multiple contract manufacturers to ensure they will get the best price. If you receive multiple quotes, make sure the estimates compare “apples-to-apples” services and offer the same level of quality. Factors to take into account include:

- What is the quality of products they produce?

- Do they have an on-time delivery record?

- What is their internal and external defect rate (in PPM)?

- Do they have a robust quality system in place (e.g., is it ISO 9001:2015 certified?)

- Do they have the experience needed to complete your project to your specs/standards?

Advantages of Contract Manufacturing

Contract manufacturing offers a broad range of advantages over investing in-house manufacturing or choosing manufacturers separately for every project, such as:

Advantages of Contract Manufacturing

Contract manufacturing offers a broad range of advantages over investing in-house manufacturing or choosing manufacturers separately for every project, such as:

-

Increased Cost Savings

In a contract manufacturing relationship, you (as the contracting company) do not have to purchase the expensive equipment or hire the skilled employees necessary to produce and assemble components in-house; the contract manufacturer should already have the modern, well-maintained equipment and experts familiar with manufacturing operations that are needed for the project. You do not need to invest in machine setup and installation or employee training, which might otherwise be the case if these steps were performed in-house. Outsourcing manufacturing can help save you on energy expenditures, labor, repairs, maintenance, raw material bulk orders, and storage space.

-

Streamlined Operations

Contract manufacturing enables you to streamline your operations by freeing up resources that can be reallocated to core products and services. Instead of spending labor dollars on manufacturing every component in-house, you can use your internal resources to increase productivity downstream. For example, if you specialize in weld assemblies, painting, and kitting, you can subcontract the production of some or all of the raw components to a contract manufacturer, which frees up your employees to focus on the assembly process. In addition to reducing labor costs, this helps keep your employees safe and gives them opportunities to optimize their strengths.

-

Improved Scalability

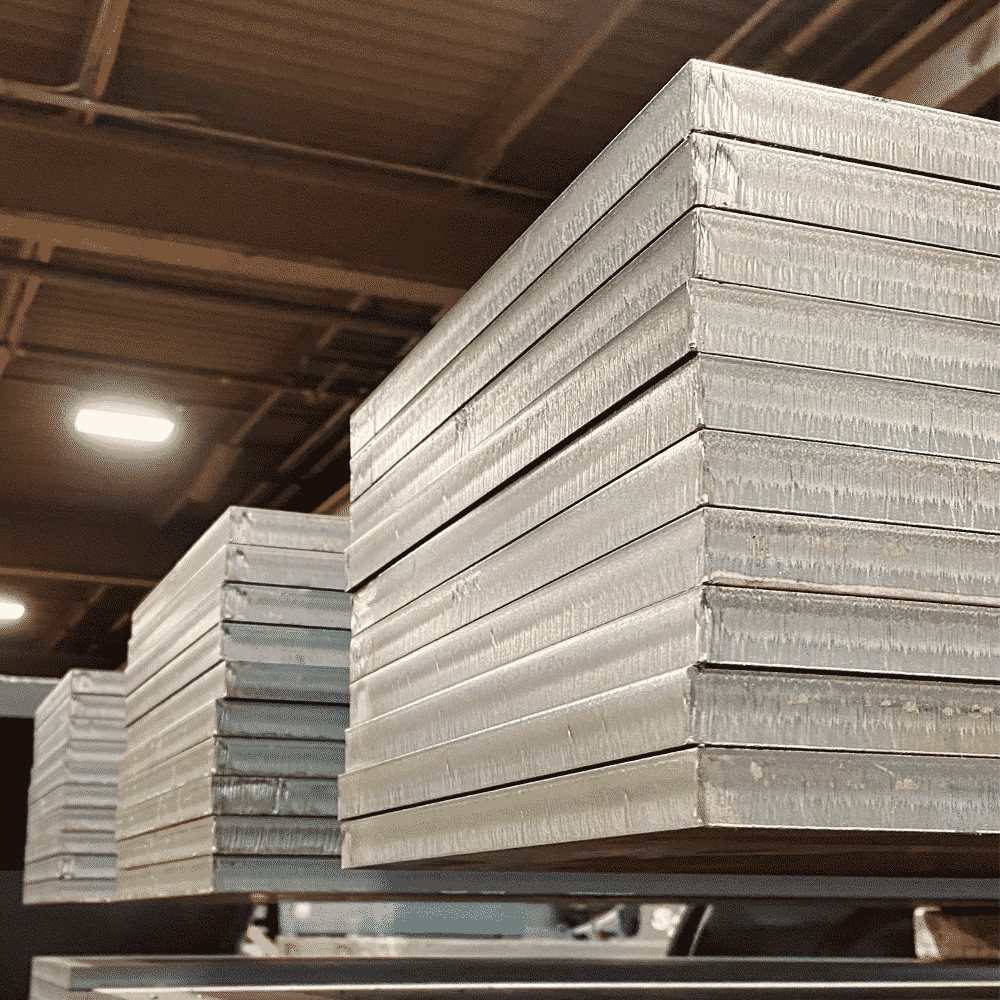

Contract manufacturers keep detailed records of each company’s manufacturing preferences and technical specifications, allowing them to quickly scale production volumes up or down to meet demand. Additionally, since they can generally procure bulk raw materials at competitive prices, they can rapidly increase production volumes without incurring high costs.

-

Enhanced Product Quality

Good contract manufacturers are experts in their field. They have the experience, expertise, and equipment necessary to produce high-quality components to strict tolerances. Instead of spending time and money hiring or training employees for in-house manufacturing, you can partner with industry experts with the tools needed to produce better (i.e., greater functionality and quality) components and products than would be possible if you made them in-house.

-

Reduced Overall Build Time

A contract manufacturer is singularly focused on producing high-quality products that arrive on time and ready for immediate assembly, thereby reducing your overall production time. If you had to produce those components in-house, you may be waiting for the material lead-time, the lead-time to fabricate, and the lead-time for assembly. By contracting your manufacturing operations to a third party, you can simplify your internal processes and accelerate production, allowing you to enjoy greater market accessibility and shorter turnaround.

Many contract manufacturers are also equipped with rapid prototyping tools, automated machines, and other advanced technologies aimed at maximizing the quality and speed of the production process. These can further help reduce overall build time and shorten the time-to-market for your products. -

Specialized Services

Contract manufacturers typically offer a range of capabilities and capacities, which allows them to accommodate a wide variety of standard or custom components and products. Typical examples include angles, bump-formed sections, channels, cones, cylinders, obrounds, segments, and custom-sized seam-welded rectangular tubes. If you choose the right partner, you do not have to worry about them not meeting your specifications or standards.

Contract Manufacturing Applications

Contract manufacturing can be used to produce anything from small automotive parts to large, welded frames for a variety of industries and applications. At G.E. Mathis Company, we pride ourselves on providing an extensive range of manufacturing services. Some of our contract-manufactured products are used in:

- Lifting equipment

- Truck cranes

- Boom components

- Frame rails

Contract Manufacturing Process at G.E. Mathis Company

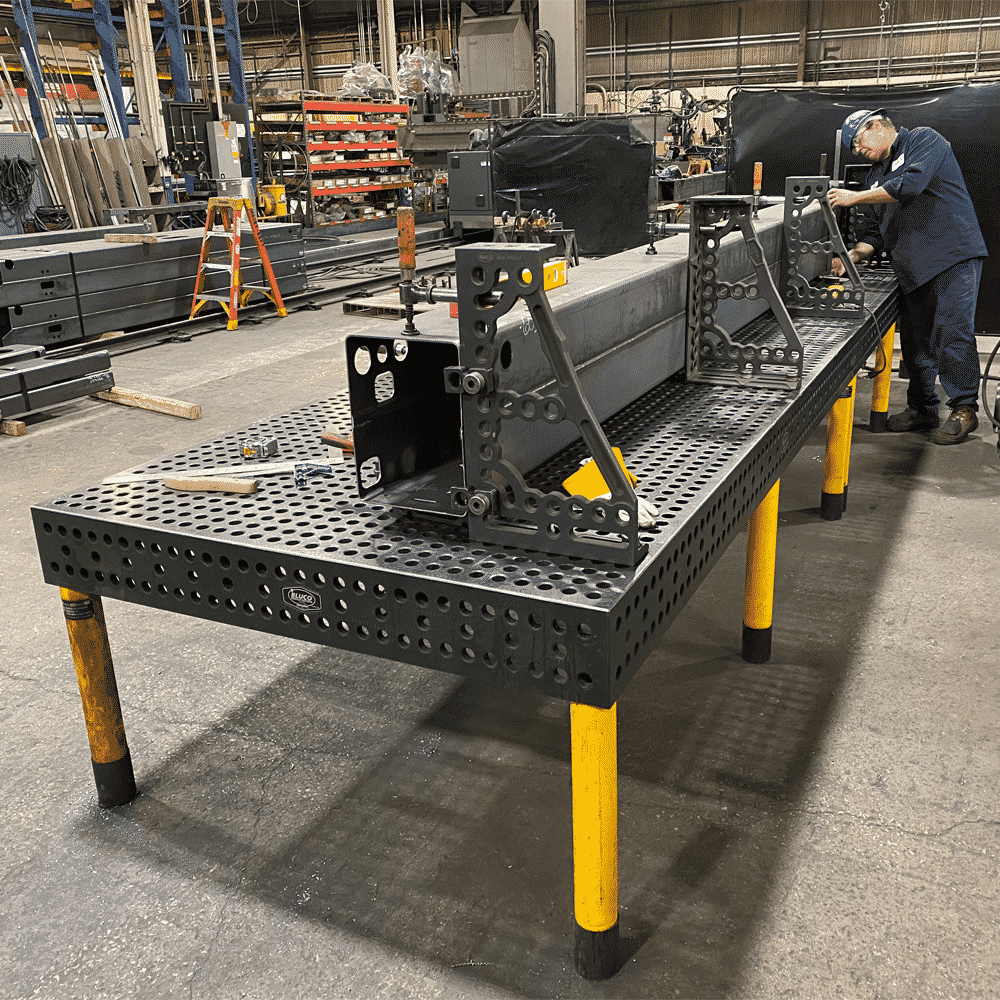

At G.E. Mathis Company, we specialize in precision metal fabrication solutions. Equipped with extensive manufacturing experience, a state-of-the-art fabrication facility, and an extensive catalog of tooling, our customers know they can trust in us for their contract manufacturing needs. Below, we outline the process we follow when tackling a contract manufacturing project.

Contract Manufacturing Process at G.E. Mathis Company

At G.E. Mathis Company, we specialize in precision metal fabrication solutions. Equipped with extensive manufacturing experience, a state-of-the-art fabrication facility, and an extensive catalog of tooling, our customers know they can trust in us for their contract manufacturing needs. Below, we outline the process we follow when tackling a contract manufacturing project.

-

Design and Quote

At the beginning of the process, the customer provides us with a drawing of the desired part(s) or component(s) with details about features and requirements. While we do not offer design or engineering services, we can use the provided drawing to determine whether we can meet the necessary specifications with our capabilities. If the drawing passes this evaluation, we provide the customer with a quote that details the materials and processes we will use for the project and the expected lead time for parts delivery. If the quote fits their project budget and schedule, we can proceed to the fabrication stage.

-

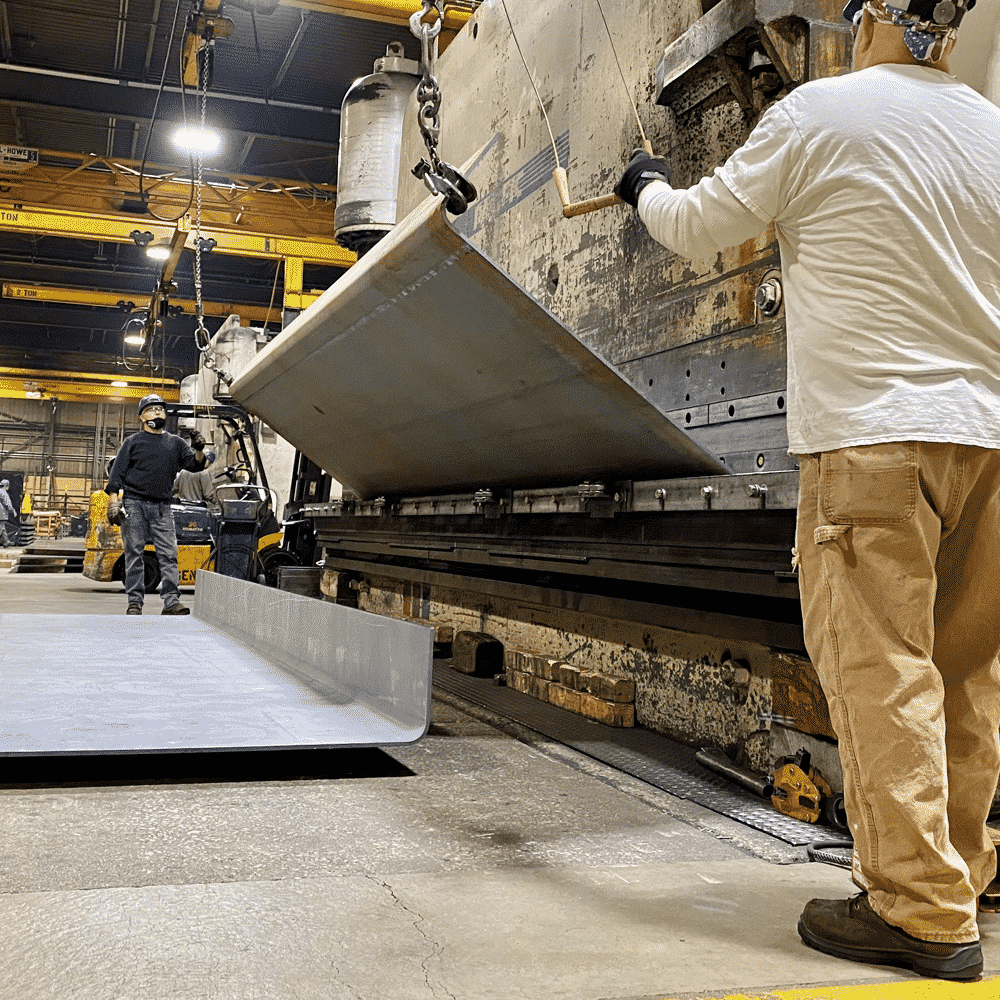

Fabrication

After the design and quote are approved, we can begin fabrication. The steps involved with the fabrication process depend on the part. For example, if the customer wants a flat plate or piece with geometry, we can simply program the equipment and cut the material. However, if the customer wants a more complicated component, the fabrication process is more involved, which extends its timeline.

We maintain consistent communication with the customer throughout the whole process to ensure the part is fabricated correctly from start to finish. We also work hard to make the pieces to the highest quality possible and deliver them on time.

Why Use G.E. Mathis Company as Your Contract Manufacturer?

Quick response and delivery times

We understand the need to produce products quickly, which is why we quote most parts within 24 hours and offer lead times as short as 1–2 weeks, depending on the project.

Broad manufacturing capabilities and capacities

Our state-of-the-art 135,000 square foot facilities can handle both small and large production volumes, from one-piece prototypes to full-scale multi-year production runs.

Skilled team members

We have a dedicated team of experienced craftsmen who provide our customers with superior components. We are also proud to maintain ISO 9001 certification.

State-of-the-art equipment

We continue to invest in the future of our company with the latest fabrication technology, so our customers know they are receiving the best manufacturing solutions in the industry.

Request Quote

Please complete the form below and we will contact you shortly.

Over 100+ Years of Experience

Trained & Certified Expertise

Reliable Customer Service

What Is Contract Manufacturing?

What Is Contract Manufacturing?