Check out our End Dump Trailer Infographic

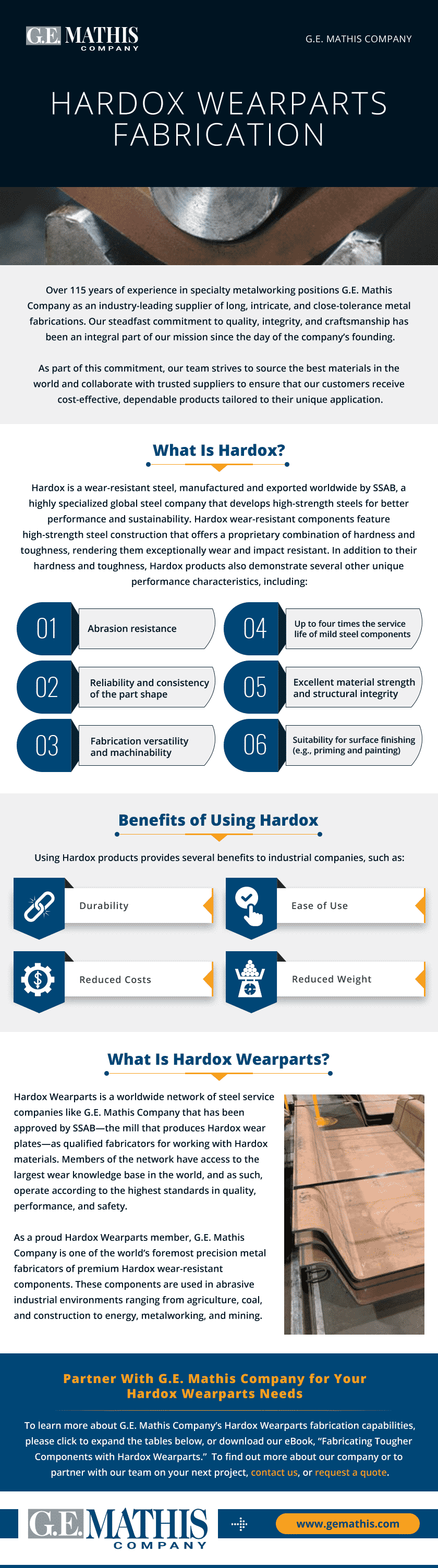

Over 100 years of experience in specialty metalworking positions G.E. Mathis Company as an industry-leading supplier of long, intricate, and close-tolerance metal fabrications. Our steadfast commitment to quality, integrity, and craftsmanship has been an integral part of our mission since the day of the company’s founding.

As part of this commitment, our team strives to source the best materials in the world and collaborate with trusted suppliers to ensure that our customers receive cost-effective, dependable products tailored to their unique application.

What Is HARDOX® Wearplate?

HARDOX® Wearplate is a wear-resistant steel, manufactured and exported worldwide by SSAB, a highly specialized global steel company that develops high-strength steels for better performance and sustainability. HARDOX® Wearplate components feature high-strength steel construction that offers a proprietary combination of hardness and toughness, rendering them exceptionally wear and impact resistant. In addition to their hardness and toughness, HARDOX® Wearplate products also demonstrate several other unique performance characteristics, including:

- Abrasion resistance

- Up to four times the service life of mild steel components

- Reliability and consistency of the part shape

- Excellent material strength and structural integrity

- Fabrication versatility and machinability

- Suitability for surface finishing (e.g., priming and painting)

These qualities make them ideal for a variety of extreme and rugged industrial applications. Regardless of the grade of the wear plate employed, the material maximizes performance and service life in any application.

Benefits of Using HARDOX® Wearplate

Using HARDOX® Wearplate products provides several benefits to industrial companies, such as:

- Durability. The high strength and wear resistance characteristic of HARDOX® Wearplate products allows them to withstand greater impact and wear stress.

- Ease of use. HARDOX® Wearplate typically maintains it’s properties for consistent, reliable results.

- Reduced costs. By bearing the majority of the load, HARDOX® Wearplate protects other components and equipment from damage during operation, maximizing their performance levels and extending their overall service life. These qualities allow facilities to increase their productivity while decreasing the cost of operation, maintenance, and repair. Some applications experience extended service life thanks to the use of HARDOX® Wearplate.

- Reduced weight. Because of the strength offered by HARDOX® Wearplate, fabricators can in some cases use thinner material and still achieve the same service life. This allows companies to reduce the weight of their equipment without sacrificing performance.

What Is HARDOX® Wearparts?

HARDOX® Wearparts is a worldwide network of steel service companies like G.E. Mathis Company that have been approved by SSAB—the mill that produces HARDOX® Wearplates—as qualified fabricators for working with HARDOX® Wearplate materials. Members of the network have access to the largest wear knowledge base in the world, and as such, operate according to the highest standards in quality, performance, and safety.

As a proud member of the HARDOX® Wearparts network, G.E. Mathis Company is one of the world’s foremost precision metal fabricators of premium HARDOX® Wearplate components. These components are used in abrasive industrial environments ranging from agriculture, coal, and construction to energy generation, metalworking, and mining.

Partner With G.E. Mathis Company for Your HARDOX® Wearparts Needs

We maintain a full staff of certified craftsmen to offer all types of fabrication using HARDOX® Wearplate. We typically have access to the following high-strength materials:

- HARDOX® 450 Plate, HARDOX® 450 Sheet

- HARDOX® 500 Plate, HARDOX® 500 Sheet

- STRENX® 100 (Domex)

- STRENX® 100 XF (Domex)

- STRENX® 110 XF (Domex)

- STRENX® 700 (Weldox)

- STRENX® 900 (Weldox)

Working to our customers’ exact specifications, we provide services that include laser cutting, thermal cutting, and welding for plates that range in thickness from .125” to 2.00”.

With our wide variety of fabrication capabilities, decades of experience, and a “whatever it takes” attitude, our team can adapt to changing needs and provide solutions that meet our customers’ exact needs and specifications.

To learn more about G.E. Mathis Company’s HARDOX® Wearparts fabrication capabilities, please click to expand the tables below, or download our eBook, “Fabricating Tougher Components with HARDOX® Wearparts.” To find out more about our company or to partner with our team on your next project, contact us, or request a quote.

Through more than a century of business, G.E. Mathis Company has remained committed to our customers, that is why we work hard to maintain our certifications. As an AWS-D1.1- and ISO 9001:2015-certified manufacturer, our customers have peace of mind, knowing they will always receive the best products and services when they choose G.E. Mathis Company.

In addition, G.E. Mathis Company can provide the following services:

- PPAP (Production Part Approval Process) – All Levels

- FAIR (First Article Inspection Report)

- Capability Studies (Statistical Process Control)

- CMRT (Conflict Minerals Reporting Template)

To learn more about our company and our metal forming capabilities, or to discuss an upcoming project, please contact us today. We look forward to working with you.

Request Quote

Please complete the form below and we will contact you shortly.

Over 100+ Years of Experience

Trained & Certified Expertise

Reliable Customer Service