What Is the Production Part Approval Process (PPAP)?

G.E. Mathis is in the business of precision. We fabricate and supply high-quality parts, perform machining and contract manufacturing services, and help our clients create innovative solutions. Since our company’s start in 1905, we’ve been a leading provider of more than just manufacturing and fabricating services—we’re also committed to quality control, excellent customer service, and ensuring each part we supply is built to last.

Establishing robust quality control processes is essential to our mission, and Production Part Approval Processes (PPAPs) are a critical aspect of this. A PPAP is a standardized way to communicate about designs and production techniques throughout a manufacturing project in the aerospace or automotive industry. Learn more about the role of PPAPs in the industry, their benefits, and how to get the most value from them during your next manufacturing project.

When Are PPAPs Required?

PPAPs are the final step in a broader Advanced Product Quality Planning (APQP) process. Its core purpose is to ensure parts manufacturers can scale up production to fulfill an order while still maintaining consistency, quality, and adherence to design requirements. PPAPs come in different levels of stringency, and customers can request their own requirements for a successful PPAP. For example, PPAP documents may include a detailed part dimensional inspection report so parts can be mapped to a layout, or they can just set general expectations.

Some of the key information a PPAP document provides includes:

- Details about part approval processes to ensure standard practices are followed

- Processes for approving part changes or method changes

- Required information that will be shared regarding part conformance and related data

- Record of conformance, including measurement of drift

- Design records that can be used to trace part design status throughout the project

While it occurs near the end of the planning process, customers can request a PPAP—and specify the details—early on in the business arrangement, such as in the provided Supplier Quality Assurance Manual (SQAM) or in a purchase order. In terms of the total manufacturing project, PPAPs are required when:

- A change is made to a planned production process

- Parts undergo a change

- A customer requests one (at any time during the product’s lifespan)

PPAP Benefits

Having a production part approval process that is standardized and fully understood by all parties can ensure a project goes smoothly and everyone has appropriate expectations for every stage of the manufacturing process. Key benefits include the following:

- Consistency: Stakeholders can use a standardized part approval process that is well-documented and offers consistency throughout the project.

- Conformity: Customers can be certain that approved parts meet their defined requirements.

- Documentation: Customers have evidence that the process is stable, remains consistent, and will follow established norms throughout production.

- Controlled Approval Process for Changes: Stakeholders can retain control of the process, even if it undergoes changes. PPAPs establish controlled approval mechanisms and channels so no changes threaten nonconformity as the project continues through later production stages.

Levels of a PPAP Submission

PPAPs can be customized to meet unique customer requirements, or they can operate within one of the five standard levels of PPAP submissions. These five levels are:

Level 1

This is a basic level. Submissions include a Part Submission Warranty (PSW) and no other documentation.

Level 2

This level requires a PSW, as well as product samples and some degree of agreed-upon supporting data.

Level 3

At this level, documentation includes a PSW, product samples, and comprehensive supporting data.

Level 4

This level offers more customized requirements. Along with a PSW, customers can set their own requirements for additional data and samples.

Level 5

This is the highest level. Documentation includes a PSW, product samples, and comprehensive supporting data. The information will remain available for stakeholders to review at the manufacturing site.

Manage Higher Quality Processes With G. E. Mathis

Quality control is our top priority at G.E. Mathis. Our company is ISO 9001:2015 certified, and we provide the following services to maintain a high level of product quality:

- Capability Studies (Statistical Process Control)

- Conflict Minerals Reporting Template (CMRT)

- First Article Inspection Report (FAIR)

- Production Part Approval Process (PPAP) (all levels available)

Our clients trust our dedication to high-quality manufacturing services and quality control management. Reach out today to learn more about quality assurance processes, metalworking capabilities, and more before starting your next order with us, or request a quote for pricing details.

First Article Inspection Reports 101 – What is FAI / FAIR

Mass production of products within the aerospace and defense industries requires an initial inspection known as the First Article Inspection (FAI) and a report on the results. G.E. Mathis is committed to providing the highest quality inspections and reports that comply with the AS9102 standards to ensure that products meet the correct specifications during manufacturing.

What is First Article Inspection?

At the beginning of a production run, all business quality systems provide a report of the inspection of one to five products straight off the manufacturing line. Regardless of whether the system is certified to ISO 9001, TS16949, or AS9102 standards, quality inspection for compliance with the documentation or customer requirements must be completed before the production run continues. Included in the review are the measurements of the layout to ensure conformity.

Other testing may include material tests and reports, appearance approvals, and more. Once all documents are received, the First Article Inspection Report (FAIR) provides the customer with a review of the product and sets the expectation for the outcome of the full production run. Customers indicate how many parts, between one and five, require inspection in the FAI before approval to continue the run.

First Article Inspection Reports (FAIR)

A First Article Inspection Report (FAIR) can be requested during a mass production run to ensure consistent product quality. However, the FAIR process typically begins by validating the manufacturing processes and the associated equipment, including when:

- Introducing New Parts

- Revising Existing Parts

- New Locations for Manufacturing

- New Supplier of Parts

- Resuming manufacturing after two years

Each FAIR has three forms that must meet the expectations outlined in the documentation. The forms include the part number accountability, product accountability, and characteristic accountability inspection forms. Two forms of inspection are carried out to ensure quality control and product reliability. The first form is dedicated to identifying the part that requires review, along with any sub-assemblies that may affect the quality of the final product. This form helps to ensure that quality issues are identified and resolved at the earliest stages of production.

The second form, product accountability, is a more comprehensive inspection process that covers all related materials, methods, and functional tests demanded by the product design. This form is crucial in ensuring that all product components function correctly and meet the required specifications. By conducting this inspection, any potential defects or issues that may arise during the product’s use can be identified and addressed, resulting in a more reliable and long-lasting product.

Finally, the characteristic accountability inspection ensures that the characteristics, dimensions, tolerances, and aesthetics align with the customer’s specifications. This form includes a detailed drawing or model pinpointing the necessary features identifiable by ballooned or bubbled numbers. A key provides details on the numbered aspects of the picture. The tools used to produce the product are included in the inspection for quality at this time.

Choosing G.E. Mathis Company for Your FAIR

Parts manufacturing is becoming more complex as the parts themselves evolve. Ensuring that each piece manufactured complies with all specified restrictions and requirements is essential to ensure products are successful after assembly. Completing a FAIR inspection during the manufacturing process ensures compliance with regulations and provides clients with product details.

Quality, integrity, and craftsmanship are at the forefront of our values at G.E. Mathis Company. Our dedication to our customers’ success is unwavering, and we strive to uphold these principles in everything we do. In addition to being an ISO 9001:2015-certified manufacturer, G.E. Mathis Company can provide the following services:

- FAIR (First Article Inspection Report)

- PPAP (Production Part Approval Process) – All Levels

- Capability Studies (Statistical Process Control)

- CMRT (Conflict Minerals Reporting Template)

Don’t hesitate to contact us today to learn more about G.E. Mathis Company and how we can apply our metal fabrication capabilities to your next project. Request a quote for your project or FAI assignment and get the expert help your facility deserves.

All About Metal Fabrication

Metal fabrication refers to the process of cutting, shaping, or molding raw or semi-raw metal materials into an end product. Depending upon the type and grade of metal, as well as the desired end product, metal fabricators may employ a variety of techniques to manufacture cost-effective, high-quality components for a wide range of industrial applications.

Types of Metal Fabrication Processes

Some of the different metalworking methods metal fabricators employ include:

Cutting

- Sawing is the oldest method of producing straight cuts through metal materials.

- Laser cutting employs a high-powered, focused laser beam of light to cut through the metal materials.

- Waterjet cutting operations utilize a high-powered water stream to cut through different materials, including metal.

- Plasma Cutting uses a mixture of swirling gases to cut through metal.

- Shearing uses two large blades to cut through metal like a giant pair of scissors.

- CNC cutting uses a computer-controlled machine to make precise cuts through metal via a variety of metal cutting techniques (e.g., laser cutting, plasma cutting, etc.)

- Die cutting employs steel rule (flatbed die cutting) or cylindrical (rotary die cutting) dies to cut out precise metal shapes.

Forming/Bending

Unlike cutting, forming (or bending) doesn’t remove material from the metal work-piece. Instead, the process alters the work-piece with a machine such as a press brake, or by a hand-held method such as with a hammer, or die to fit the required specifications.

Welding

- Submerged arc welding (SAW): This welding method employs a continuous electrode to create an arc between the welding rod and the work-piece. The addition of a thick granular flux forms a shield that protects the weld zone from atmospheric contamination during operations.

- Shielded metal arc welding (SMAW): This welding method—also referred to as stick welding—uses a welding rod coated in flux that carriers a high-power electrical current. The coating breaks down during welding operations, forming a layer of slag and a gas shield that protects the weld as it cools.

- Gas metal arc welding (GMAW): This welding method—also known as MIG welding—relies on an adjustable and continuous solid wire electrode. During operations, the electric arc formed between the work-piece and the electrode heats and melts the base metals to form the weld.

- Gas tungsten arc welding (GTAW): This welding method—also called TIG welding—requires the use of a non-consumable tungsten electrode. It produces strong welds without fillers.

- Fluxed core arc welding (FCAW): This welding method is similar to GMAW welding, except it utilizes a tubular wire electrode filled with flux rather than a solid wire electrode. Self-shielded FCAW operations rely only on flux to protect the weld zone, while dual-shielded FCAW operations rely on both flux and an external shielding gas.

Stamping

Uses a top and bottom die molded into a custom 3-dimensional shape. When the metal is pressed between the two dies, it conforms to the desired shape. This process is used to make many complex metal shapes, such as body panels for the automotive industry.

Machining

Uses CNC-controlled machinery with various cutting tools to rapidly produce a custom 3-dimensional metal component by removing unwanted materials.

Advantages and Applications of Metal Fabrication Processes

There are several different types of metal fabrication processes employed by industry professionals to produce metal parts and products. As each process utilizes different techniques and equipment, it offers distinct advantages and best use cases.

Advantages and Applications of Cutting

Perhaps the most ubiquitous of all metal fabrication processes, cutting can be employed alongside other methods. In general, cutting offers several advantages with more modern techniques providing enhanced manufacturing capabilities. Some of the advantages of using cutting to fabricate metal parts include:

- Greater precision

- Higher repeatability

- Faster production speeds

- Better cost-effectiveness

Advantages and Applications of Forming/Bending

Metal fabricators use forming operations—e.g., rolling, indenting, and bending—to produce many metal parts, such as pipes, enclosures, and boxes. The advantages of using these operations include:

- Broader product capabilities

- Greater part design flexibility, including for complex shapes and geometries

Advantages and Applications of Welding

In general, welding allows for minimal waste production, reduced labor and material costs, and process portability. Each of the individual welding techniques also offers unique benefits. For example:

TIG Welding Benefits

Commonly used for aluminum and aluminum alloys, TIG welding produces a better surface finish than MIG welding and doesn’t require a filler material to produce the weld.

MIG Welding Benefits

Commonly used on steel, MIG welding does require the use of consumable filler material (i.e., the feeding wire). However, compared to TIG welding, it is faster and easier to control.

Sticking Welding Benefits

Commonly used on iron and steel, stick welding is the simplest welding technique. As such, it is used extensively for industrial fabrication applications.

Advantages and Applications of Stamping

Stamped parts are found across a diverse set of industries. The stamping process allows for:

- Higher precision and accuracy

- Faster production speeds

- Lower per-unit production costs (for high-volume runs)

Advantages and Applications of Machining

Machining is a broad industrial term for subtractive manufacturing processes, such as drilling, milling, and turning. While some companies still rely on manual machining units, many companies have adopted the use of computer numerical control (CNC) machining equipment. The latter enables industry professionals to achieve the following:

- Tighter tolerances

- Higher production consistency

- Greater cost-efficiency (for small to medium runs)

Metal Fabrication Solutions From G.E. Mathis Company

At G.E. Mathis Company, we offer industry-leading metal fabrication services to customers across a diverse set of industries. Equipped with a 135,000 square foot, state-of-the-art manufacturing facility and over a century of industry experience, our team provides:

Precision Laser Processing

Precision CNC Plasma Cutting

We utilize 4-axis machines capable of high-definition cutting action to provide precision CNC plasma cutting services. The equipment’s 400 amp, straight, dual-head, and contour beveling capabilities help us provide superior results across a wide variety of materials, including carbon, aluminum, stainless steel, and exotic metals.

Precision Forming/Bending

For our precision forming/bending operations, our team utilizes eight hydraulic press brakes, including two equipped with CNC capabilities. These machines feature 400- to 1,000-ton capacities and accommodate thicknesses up to 2 inches and lengths of 20, 20, 30, 23, 25, 40, and 48 feet.

Some of the formed/bent components we fabricate include:

- Cones

- Cylinders

- Ob-rounds

- Segments

- Channels and angles

- Bump formed sections

We process a variety of materials in these operations, such as:

- Carbon steel

- Stainless steel

- Aluminum

- Brass

- Bronze

- Copper

- Titanium

- Hardox® wear plate

Precision Welding

Our AWS-certified welders are capable of providing precision arc and MIG welding services using CNC-controlled welding and fully automated processes, including:

- Dual-wire submerged arc welding

- Flux cored arc welding—i.e., FCAW

- Gas metal arc welding—i.e., GMAW

- Gas tungsten arc welding—i.e., GTAW

- Shielded metal arc welding—i.e., SMAW

- Submerged arc welding—i.e., SAW

We weld materials up to 12 feet wide and 50 feet long, including:

- Carbon steel

- Stainless steel

- Aluminum

- Hardox® wear plate

HARDOX® Wearparts Fabrication

- HARDOX 450

- HARDOX 500

- STRENX 100 (Domex® 100)

- STRENX 110 (Domex® 110)

- STRENX 700

- WELDOX 100

- WELDOX 110

These products are available in up to 2-inch thicknesses with industry-leading tolerances to meet even the most demanding application requirements.

In addition to being an ISO 9001:2015-certified manufacturer, G.E. Mathis Company can provide the following services:

- PPAP (Production Part Approval Process) – All Levels

- FAIR (First Article Inspection Report)

- Capability Studies (Statistical Process Control)

- CMRT (Conflict Minerals Reporting Template)

At G.E. Mathis Company, we have over a century of experience providing metal fabrication solutions. If you have a metal fabrication project, we can meet your needs. Contact us today for more information about our metal fabrication capabilities or request a quote from one of our experts for your next project.

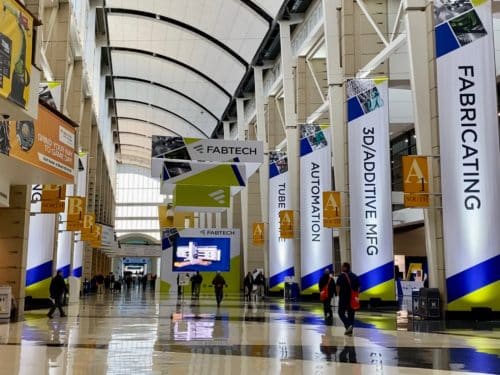

Our Experience at FABTECH

It’s always a great experience for us to interact with other manufacturers and see what new technologies are trending in the industry. Trade shows and conferences provide us the chance to do just that. This year, G.E. Mathis Company sent a team to attend the FABTECH trade show, which took place in Chicago in November.

As the show features equipment vendors, fabricators, and businesses that sell services, it is the perfect opportunity for a company like ours to share our capabilities and see what else is happening throughout the industry. For us, it was nice to gain exposure to new people, and we hope to be able to build on the leads we generated. Overall, we thought this year’s show was a success, and we look forward to the industry’s future events. We hope to see you there!

GE Mathis Comapny: Growing Up in 2013

What do we want to achieve in 2013? As the new year gets off to a good start, all of us here at G.E. Mathis Company have reflected on the year that was and are setting future goals. So what do we have in mind?

How do we hope to grow ourselves and contribute to the industry? Currently, we are expanding our capabilities, so that we continuously meet the requirements of our customers. As we continue to see positive signs of improvement in the economy, we hope that our capabilities can contribute to this progress. Recently, we invested in new machinery that provides us with unique welding capabilities. After putting this machine into operation, we hope to service a wide range of applications and industries.

What’s one of our biggest goals for 2013? To help contribute to the growth of the economy and manufacturing, and to see industry reach the height it held before the recession. By advancing our capabilities and services, we have high expectations for our business and that of the manufacturing world!

Why we are Celebrating American Manufacturing

- Economic benefits: The more manufacturing we can do domestically, the less we rely on others and the better state our economy is in. It is economically beneficial for us to export more than we import—the more we can manufacture ourselves, the more solid our economy will be.

- Higher employment: Not only does manufacturing in the U.S provide more jobs and livelihoods for workers, but it creates even further demand for jobs. For example, here at G.E. Mathis Company, we produce components and products that our clients use for their products—therefore, our work is in turn spurring more work once ours is completed.

- Higher quality: We are proud not only to be considered “Made in America,” but also to meet the highest quality standards. Not to mention, if you work with a domestic manufacturer, you have the option to check in on the production process and ensure that the products you are receiving meet your specifications.

- Shorter lead times: With manufacturing being done domestically, the turn-around time is cut down dramatically.

To learn more about American manufacturing, join us in celebrating MFG Day!

A Tradition of Quality Since 1905

Welcome to G.E. Mathis Company and our blog, the space where we plan to open a dialogue with you, our customers, and all those interested in the metal fabrication industry. We enjoy a rich history of quality, integrity, and craftsmanship that began with our great grandfather, a ‘tin knocker’ who opened a sheet metal fabrication shop here in Chicago at the turn of the 20th century.

With the knowledge and skill passed through the hands of four generations, G.E. Mathis Company has become a nationwide supplier of long, intricate, and close tolerance fabrications. We operate a large, 135,000 sq. ft. facility housed in three separate buildings equipped with some of the largest and most versatile metal fabrication equipment available today, as well as 21 overhead bridge-type cranes for efficient material handling. Advanced production and control technologies allow us to deliver parts with the tightest tolerances in the industry, and our ISO 9001:2015 certified quality assurance program ensures product integrity and customer satisfaction.

Providing a full range of services including laser cutting, plasma cutting, press brake forming, welding and metal finishing, we are excited about furthering our capabilities: we are supplementing our current equipment list with a new large press brake and a submerged arc and MIG welding system at the end of the summer. We hope you take advantage of our expanded offerings in the fall!

Thanks for stopping by to read about G.E. Mathis Company; we hope to see you on these pages again soon. If you would like to learn more about our capabilities, please visit our website, contact us today or request a quote for your next project.