Welding Dissimilar Metals

Dissimilar metal welding processes join two different metal alloys through welding. There are many dissimilar metal welding applications and benefits. Fusing metals allows you to get more out of each metal’s unique properties. For example, while aluminum is light and corrosion-resistant, it is costlier than other metals, like steel.

Since metals have different properties, fusing the right dissimilar metals is essential to avoid corrosion or weak connections. That’s why evaluation of metals and filler material is critical before selecting the welding method. When done right, welding dissimilar metals can improve the overall performance of the metals and lower costs.

Dissimilar Welding Process

There is no simple, standardized approach when it comes to welding dissimilar metals. As such, the welder needs to analyze the situation before selecting a process. For example, the welder may need to add transition materials to the metal surfaces or opt for nonstandard welding methods depending on the application.

There is no simple, standardized approach when it comes to welding dissimilar metals. As such, the welder needs to analyze the situation before selecting a process. For example, the welder may need to add transition materials to the metal surfaces or opt for nonstandard welding methods depending on the application.

What makes welding dissimilar metals difficult is the variation in properties of different metals. There are several things to keep in mind when welding dissimilar metals, including:

Melting Points of the Metals

Many metals melt at different temperatures. For example, aluminum melts at around 1220 °F (660 °C), while steel melts at 2,500°F (1,370 °C). Welding quickly and using high heat can preserve the integrity of the finished weld. So, you may need to adjust your welding technique to ensure metals are melting and combining smoothly.

Coefficients of Thermal Expansion of Both Metals

The coefficient of thermal expansion indicates how the metal’s size changes when exposed to heat. If the coefficient between both metals varies greatly, it creates the risk of internal residual stress in the intermetallic zone after the fusion, impacting the lifespan of your newly welded metal.

Electrochemical Difference

Variation in electrochemical properties of metals can cause corrosion in the intermetallic zone. Corrosion levels are often directly proportional to the electrochemical difference. So, you are likely to experience more corrosion as the electrochemical difference increases between the two metals. Minimizing the intermetallic zone can reduce the risk of joint failure on the completed weld.

Solubility of Each

For the welding process to be successful, the two dissimilar metals must have the same solubility. Solubility is the ability of two metals to blend to form a solid solution. Using a third metal that is soluble with both original materials can solve the solubility problem.

Final Use of the Welded Component

Consider the final use when choosing the welding method for dissimilar materials. For example, welded joints that come in contact with electrolyte fluids need a filler material with a higher corrosion resistance than the metals to slow down the rate of galvanic corrosion.

Can Dissimilar Metals be Welded?

Benefits of Welding Dissimilar Metals

Welding dissimilar metals presents a range of benefits, including:

- Improved Joint Strength: It controls the phase formation in the joint by restricting the reacting time and the interlayer composition.

- More Combination Options: It is possible to make many combinations by welding dissimilar metals than conventional welding.

- Cost-Effective and Convenient: Welding dissimilar metals allows the opportunity to use cheaper materials, or what is available, and strengthen them by welding them to stronger metals.

Welding Techniques for Dissimilar Metals

Here are the top three welding techniques for dissimilar metals:

Fusion Welds: Fusion welding uses heat to fuse or join two or more materials by heating them to a melting point. The welding process can be categorized based on heat sources. These include high energy, electrical resistance, electric arc, and gas.

- Low-Dilution Welding: Low-dilution welding uses a pulse arc weld, electron beam, or laser welding dissimilar metals. The amount of base metal melted is small, and fillers are often unnecessary.

- Non-Fusion Joining of Dissimilar Materials: Non-fusion joint method involves diffusion welding, explosion welding, friction welding, and soldering and brazing. It works well when connecting aluminum and steel, stainless steel and nickel alloys, and steel and copper alloy pairs.

Work with G.E. Mathis Company

G.E. Mathis Company is one of the top providers of precision welding services. Our 135,000-square-foot facility in Chicago, IL can handle large weldments and still achieve the tightest tolerances available in the market today.

G.E. Mathis Company provides a range of precision welding services to meet the varying needs of customers. We also provide fully automated and CNC-controlled welding services for high-precision and large-scale projects and handle virtually any customer specification.

In addition to being an ISO 9001:2015-certified manufacturer, G.E. Mathis Company can provide the following services:

- PPAP (Production Part Approval Process) – All Levels

- FAIR (First Article Inspection Report)

- Capability Studies (Statistical Process Control)

- CMRT (Conflict Minerals Reporting Template)

Contact us today to learn more about our welding services, or request a quote to start your next project.

Understanding the MIG Welding Process

Metal inert gas (MIG) welding is a type of arc welding that joins metal workpieces using an electric current, a consumable wire electrode, and an inert shielding gas such as helium or argon. The MIG welding process offers many advantages, making it a popular method for a wide range of applications and industries. Here, we will describe how MIG welding works, how it’s used, and its many unique benefits.

What Is MIG Welding?

MIG welding, also known as gas metal arc welding (GMAW), uses an adjustable, continuously fed solid wire electrode to create welded joints. This versatile and easily automated welding method only requires the welder to guide the welding gun along the fusion point at the proper orientation and position. An electric arc forms between the workpiece and the electrode, which generates enough heat to melt and join the metals.

How Is MIG Welding Used?

MIG welding utilizes an electrical current from a non-consumable or consumable solid wire electrode. As the electrical current generates heat, the filler materials melt to join two or more metal workpieces. In many cases, the filler material doubles as the electrode. This type of arc welding can be performed manually by a trained technician, or the process can be automated through moving equipment to ensure proper positioning and orientation.

Benefits of MIG Welding

Commonly used for welding steel materials, MIG welding is versatile, relatively fast, and easy to control, making it a popular welding technique for various applications. Other key benefits of MIG welding include:

- Speed. Compared to other welding methods such as TIG welding, MIG welding offers faster process speeds.

- Automated or manual. MIG welding units can be fully or partially automated, or they can be entirely manual based on the needs of each individual project.

- Ease of Use. MIG welding, though it requires a consumable electrode or filler material, is simple and easy to control. It also offers easy cleanup and a lack of chipping.

- Versatility. MIG welding can be used with stainless steel and multiple other materials. This technique is also versatile in terms of weld position and joint thickness.

- Environmentally friendly. The wire electrodes are fully consumed for minimal product waste, making MIG welding more environmentally friendly than alternative methods.

G.E. Mathis Company Welding Solutions

At G.E. Mathis Company, we use the latest manufacturing technology to offer precision MIG welding services for industries such as defense, construction, aerospace, and agriculture. Our state-of-the-art facilities are equipped with precision tooling equipment, Bluco fixture tables, and other varied fixtures that allow us to handle weldments of almost any size and shape. We can work with a wide range of metals and specialty alloys, including carbon steel, stainless steel, high-strength steel including STRENX® Performance Steel, and Abrasion-Resistant steel such as AR400, HARDOX® Wearplate, HARDOX® 450, and HARDOX® 500TUF .

In addition to being an ISO 9001:2015-certified manufacturer, G.E. Mathis Company can provide the following services:

- PPAP (Production Part Approval Process) – All Levels

- FAIR (First Article Inspection Report)

- Capability Studies (Statistical Process Control)

- CMRT (Conflict Minerals Reporting Template)

G.E. Mathis Company is dedicated to providing the highest levels of quality, craftsmanship, and integrity in the industry. We work with our customers to help them reach their goals by providing personalized service, expertise, and stringent quality assurance. For more information about our MIG welding services and other metalworking capabilities, contact us today or request a quote for your next project.

Considerations for Welding Stainless Steel

For more than a century, G.E. Mathis Company has been a reputable name in the metalworking industry. Our extensive selection of metal fabrication services includes specialized stainless steel welding for industries ranging from chemical manufacturing and food service to construction and defense.

Welding Process Overview

Stainless steel welding operates under the same basic welding principles as all metals. Just like other welding techniques, heat and sometimes pressure are applied to the base material at the point where you are joining two or more pieces of metal. Depending on the specific project and process, filler material may be melted along the joint and then allowed to cool.

The resultant material is a hard metal bonded to the surface material of each piece that holds them together in a solid joint. In order to prevent weak joints, the filler material must have a level of strength and hardness equal to the component pieces. The strength provided by the joining material is what ultimately provides a stronger bond when compared to other techniques, such as soldering or brazing.

Stainless Steel Welding Methods

Stainless steel welding typically involves some form of arc welding combined with specialized work holding solutions known as fixtures. Fixture welding uses a specialized tool to hold the stainless steel pieces in place. This ensures straight, clean welded seams without inconsistencies. To facilitate numerous clamp and brace configurations, a fixture table is constructed with numerous holes and openings.

This allows the welder to weld a wide range of sizes and shapes from numerous angles without worrying about unwanted movement or shifting. Fixture welding is particularly useful for stainless steel, as it allows a high degree of control over the position of the welding equipment and the component parts.

For the actual welding process, arc welding stainless steel offers the highest level of temperature control, which helps to ensure strong and accurate welds. In addition, a variety of filler materials can be used to improve weld strength when combined with the stainless steel material. The two most common arc welding techniques used with stainless steel include tungsten inert gas (TIG) welding and metal inert gas (MIG) welding. Each method uses a different approach to achieve the desired results.

Tungsten Inert Gas Welding

Tungsten inert gas (TIG) welding is a form of arc welding that uses a non-consumable tungsten electrode to create an arc of electrical current. The arc is shielded by an inert gas such as helium or argon and used to heat the filler material to weld multiple pieces together. TIG welding is highly valued for use in stainless steel welding because the level of heat can be easily controlled remotely with a foot pedal or fingertip controls.

Metal Inert Gas Welding

Metal inert gas (MIG) welding uses an electrical current from a consumable or non-consumable electrode. The heat generated by the electrical current is used to melt filler materials to join two or more metal pieces together. This form of arc welding can be automated or performed manually, and the filler material can double as the electrode.

G.E. Mathis Company Welding Solutions

In addition to being an ISO 9001:2015-certified manufacturer, G.E. Mathis Company can provide the following services:

- PPAP (Production Part Approval Process) – All Levels

- FAIR (First Article Inspection Report)

- Capability Studies (Statistical Process Control)

- CMRT (Conflict Minerals Reporting Template)

G.E. Mathis Company is dedicated to providing the highest levels of quality, integrity, and craftsmanship in the industry. We help our customers reach their goals by providing a combination of expertise, rigorous quality assurance, and personalized service. To learn more about G.E. Mathis Company’s stainless steel welding and other metalworking capabilities, contact us or request a quote today.

All About Metal Fabrication

Metal fabrication refers to the process of cutting, shaping, or molding raw or semi-raw metal materials into an end product. Depending upon the type and grade of metal, as well as the desired end product, metal fabricators may employ a variety of techniques to manufacture cost-effective, high-quality components for a wide range of industrial applications.

Types of Metal Fabrication Processes

Some of the different metalworking methods metal fabricators employ include:

Cutting

- Sawing is the oldest method of producing straight cuts through metal materials.

- Laser cutting employs a high-powered, focused laser beam of light to cut through the metal materials.

- Waterjet cutting operations utilize a high-powered water stream to cut through different materials, including metal.

- Plasma Cutting uses a mixture of swirling gases to cut through metal.

- Shearing uses two large blades to cut through metal like a giant pair of scissors.

- CNC cutting uses a computer-controlled machine to make precise cuts through metal via a variety of metal cutting techniques (e.g., laser cutting, plasma cutting, etc.)

- Die cutting employs steel rule (flatbed die cutting) or cylindrical (rotary die cutting) dies to cut out precise metal shapes.

Forming/Bending

Unlike cutting, forming (or bending) doesn’t remove material from the metal work-piece. Instead, the process alters the work-piece with a machine such as a press brake, or by a hand-held method such as with a hammer, or die to fit the required specifications.

Welding

- Submerged arc welding (SAW): This welding method employs a continuous electrode to create an arc between the welding rod and the work-piece. The addition of a thick granular flux forms a shield that protects the weld zone from atmospheric contamination during operations.

- Shielded metal arc welding (SMAW): This welding method—also referred to as stick welding—uses a welding rod coated in flux that carriers a high-power electrical current. The coating breaks down during welding operations, forming a layer of slag and a gas shield that protects the weld as it cools.

- Gas metal arc welding (GMAW): This welding method—also known as MIG welding—relies on an adjustable and continuous solid wire electrode. During operations, the electric arc formed between the work-piece and the electrode heats and melts the base metals to form the weld.

- Gas tungsten arc welding (GTAW): This welding method—also called TIG welding—requires the use of a non-consumable tungsten electrode. It produces strong welds without fillers.

- Fluxed core arc welding (FCAW): This welding method is similar to GMAW welding, except it utilizes a tubular wire electrode filled with flux rather than a solid wire electrode. Self-shielded FCAW operations rely only on flux to protect the weld zone, while dual-shielded FCAW operations rely on both flux and an external shielding gas.

Stamping

Uses a top and bottom die molded into a custom 3-dimensional shape. When the metal is pressed between the two dies, it conforms to the desired shape. This process is used to make many complex metal shapes, such as body panels for the automotive industry.

Machining

Uses CNC-controlled machinery with various cutting tools to rapidly produce a custom 3-dimensional metal component by removing unwanted materials.

Advantages and Applications of Metal Fabrication Processes

There are several different types of metal fabrication processes employed by industry professionals to produce metal parts and products. As each process utilizes different techniques and equipment, it offers distinct advantages and best use cases.

Advantages and Applications of Cutting

Perhaps the most ubiquitous of all metal fabrication processes, cutting can be employed alongside other methods. In general, cutting offers several advantages with more modern techniques providing enhanced manufacturing capabilities. Some of the advantages of using cutting to fabricate metal parts include:

- Greater precision

- Higher repeatability

- Faster production speeds

- Better cost-effectiveness

Advantages and Applications of Forming/Bending

Metal fabricators use forming operations—e.g., rolling, indenting, and bending—to produce many metal parts, such as pipes, enclosures, and boxes. The advantages of using these operations include:

- Broader product capabilities

- Greater part design flexibility, including for complex shapes and geometries

Advantages and Applications of Welding

In general, welding allows for minimal waste production, reduced labor and material costs, and process portability. Each of the individual welding techniques also offers unique benefits. For example:

TIG Welding Benefits

Commonly used for aluminum and aluminum alloys, TIG welding produces a better surface finish than MIG welding and doesn’t require a filler material to produce the weld.

MIG Welding Benefits

Commonly used on steel, MIG welding does require the use of consumable filler material (i.e., the feeding wire). However, compared to TIG welding, it is faster and easier to control.

Sticking Welding Benefits

Commonly used on iron and steel, stick welding is the simplest welding technique. As such, it is used extensively for industrial fabrication applications.

Advantages and Applications of Stamping

Stamped parts are found across a diverse set of industries. The stamping process allows for:

- Higher precision and accuracy

- Faster production speeds

- Lower per-unit production costs (for high-volume runs)

Advantages and Applications of Machining

Machining is a broad industrial term for subtractive manufacturing processes, such as drilling, milling, and turning. While some companies still rely on manual machining units, many companies have adopted the use of computer numerical control (CNC) machining equipment. The latter enables industry professionals to achieve the following:

- Tighter tolerances

- Higher production consistency

- Greater cost-efficiency (for small to medium runs)

Metal Fabrication Solutions From G.E. Mathis Company

At G.E. Mathis Company, we offer industry-leading metal fabrication services to customers across a diverse set of industries. Equipped with a 135,000 square foot, state-of-the-art manufacturing facility and over a century of industry experience, our team provides:

Precision Laser Processing

Precision CNC Plasma Cutting

We utilize 4-axis machines capable of high-definition cutting action to provide precision CNC plasma cutting services. The equipment’s 400 amp, straight, dual-head, and contour beveling capabilities help us provide superior results across a wide variety of materials, including carbon, aluminum, stainless steel, and exotic metals.

Precision Forming/Bending

For our precision forming/bending operations, our team utilizes eight hydraulic press brakes, including two equipped with CNC capabilities. These machines feature 400- to 1,000-ton capacities and accommodate thicknesses up to 2 inches and lengths of 20, 20, 30, 23, 25, 40, and 48 feet.

Some of the formed/bent components we fabricate include:

- Cones

- Cylinders

- Ob-rounds

- Segments

- Channels and angles

- Bump formed sections

We process a variety of materials in these operations, such as:

- Carbon steel

- Stainless steel

- Aluminum

- Brass

- Bronze

- Copper

- Titanium

- Hardox® wear plate

Precision Welding

Our AWS-certified welders are capable of providing precision arc and MIG welding services using CNC-controlled welding and fully automated processes, including:

- Dual-wire submerged arc welding

- Flux cored arc welding—i.e., FCAW

- Gas metal arc welding—i.e., GMAW

- Gas tungsten arc welding—i.e., GTAW

- Shielded metal arc welding—i.e., SMAW

- Submerged arc welding—i.e., SAW

We weld materials up to 12 feet wide and 50 feet long, including:

- Carbon steel

- Stainless steel

- Aluminum

- Hardox® wear plate

HARDOX® Wearparts Fabrication

- HARDOX 450

- HARDOX 500

- STRENX 100 (Domex® 100)

- STRENX 110 (Domex® 110)

- STRENX 700

- WELDOX 100

- WELDOX 110

These products are available in up to 2-inch thicknesses with industry-leading tolerances to meet even the most demanding application requirements.

In addition to being an ISO 9001:2015-certified manufacturer, G.E. Mathis Company can provide the following services:

- PPAP (Production Part Approval Process) – All Levels

- FAIR (First Article Inspection Report)

- Capability Studies (Statistical Process Control)

- CMRT (Conflict Minerals Reporting Template)

At G.E. Mathis Company, we have over a century of experience providing metal fabrication solutions. If you have a metal fabrication project, we can meet your needs. Contact us today for more information about our metal fabrication capabilities or request a quote from one of our experts for your next project.

Understanding Gas Metal Arc Welding

GMAW operations use two types of gases—inert or active—each of which characterizes one of the process’s two forms: MIG and MAG. Metal inert gas (MIG) welding uses inert gas during the welding process, while metal active gas (MAG) welding uses active gas. In addition to being categorized based on the assist gas employed, GMAW operations can also be classified based on their modes of transfer.

Although GMAW typically uses a constant voltage and direct current power system, the process also employs alternating current systems with a range of different amps and voltages and varying electrode diameters. Additionally, depending on the requirements and restriction of the welding application, GMAW can be configured to be semi-automatic—i.e., require some human operator involvement—or fully automatic with mechanized control. These options make the process a viable solution for a wide range of fastening applications.

Transfer Modes of GMAW

As noted above, GMAW uses different metal transfer modes. Each mode offers distinct characteristics and best use cases and is largely dependent on the specific welding process, power supply, and consumable employed. A variety of factors influence which transfer mode should be used for a GMAW application, including the amount and type of current, electrode chemistry, surface, and diameter, type and delivery of shielding gas, and contact-to-workpiece distance. The choice of transfer mode affects which filler metal is ideal.

The four modes of GMAW transfer include:

- Globular. This mode uses CO2 shielding gas, which is less expensive than other shielding gases such as argon. Although it offers a higher deposition rate that allows for faster welding speeds, it generates more heat than other modes, resulting in uneven weld surfaces and greater spatter production. To combat these disadvantages, welding operations that use the globular metal transfer mode require thicker materials and entirely flat positioning.

- Short-Circuiting. Welding operations that use the short-circuiting metal transfer mode are also referred to as short arc GMAW or SCT. In this transfer mode, short-circuiting occurs as the electrode contacts the workpiece, providing transfer rates of between 20 and 200 times per second. It uses a mixture of 75% argon and 25% CO2 or three-part gas mixtures as its shielding gas and can be used for thin (less than ¼ inch) stock of ferrous metals and pipes without backing.

- Spray. In the spray transfer mode, molten droplets of material—usually smaller than the diameter of the electrode—spray across the workpiece. This mode uses a variety of mixtures from 80% to 98% argon with 2% to 20% CO2 and requires higher voltage or amperage, faster wire feed rates, thicker materials, and horizontal or flat positioning.

- Pulse-Spray. The main characteristic of this mode is an alternation between a high voltage spray current and a low background current. This quality enhances the spray transfer process by supercooling the weld pool during the low current cycle and reduces heat generation and distortion.

Advantages of GMAW

Each of the transfer modes provides its own advantages in specific applications. However, there are some general advantages associated with using gas metal arc welding, including:

- Ability to be configured for semi-automatic or fully automated operation

- Versatility regarding material and joint thickness

- Ease of cleanup and lack of chipping

- Welding position flexibility

- Cost-effectiveness

- Process speed

- Environmental friendliness (minimal waste is produced as electrodes are fully consumed)

Applications of GMAW

GMAW arose as a solution for welding aluminum and other non-ferrous materials. However, due to its capacity to speed up the welding process, its use has spread to steel and stainless steel applications. Its versatility allows for its use in any industry and with a wide range of materials. Some of the most common applications for GMAW include:

- Automotive production and maintenance operations

- Robotic assembly lines

- Pipe fitting

- Track construction and maintenance operations in the railway industry

Contact G.E. Mathis Company for Your GMAW Needs

At G.E. Mathis, we offer precision arc and MIG welding services to customers across a broad range of industries, including agriculture, mining, aerospace, military, and construction. Armed with a state-of-the-art facility and years of industry experience, our team of highly skilled welders has the tools and expertise necessary to offer a variety of welding services. In addition to GMAW, we provide:

- Dual wire submerged arc/MIG Welding

- Flux core arc welding (FCAW)

- Gas tungsten arc welding (GTAW)

- Seam welding

- Shielded metal arc welding (SMAW)

- Submerged arc welding (SAW)

Located in Chicago, Illinois, our 135,000 square foot facility—equipped with fully automated, CNC-controlled welding equipment—allows us to meet virtually any customer specifications on high precision, large volume projects. Our capabilities include:

- Production capacities for large weldments up to 12 feet wide or 80 feet long with the tightest tolerances available in the industry

- Material capabilities for a wide range of metals, such as carbon steel, stainless steel, HARDOX® Wearplate, STRENX®, and other alloys

To ensure the quality of our products, both our personnel and facilities maintain compliance with the highest certification standards, such as AWS D1.1, D1.6, D9.1, and D10.9.

In addition to being an ISO 9001:2015-certified manufacturer, G.E. Mathis Company can provide the following services:

- PPAP (Production Part Approval Process) – All Levels

- FAIR (First Article Inspection Report)

- Capability Studies (Statistical Process Control)

- CMRT (Conflict Minerals Reporting Template)

Contact us today for more information about our gas metal arc welding capabilities or request a quote from one of our experts for your next project.

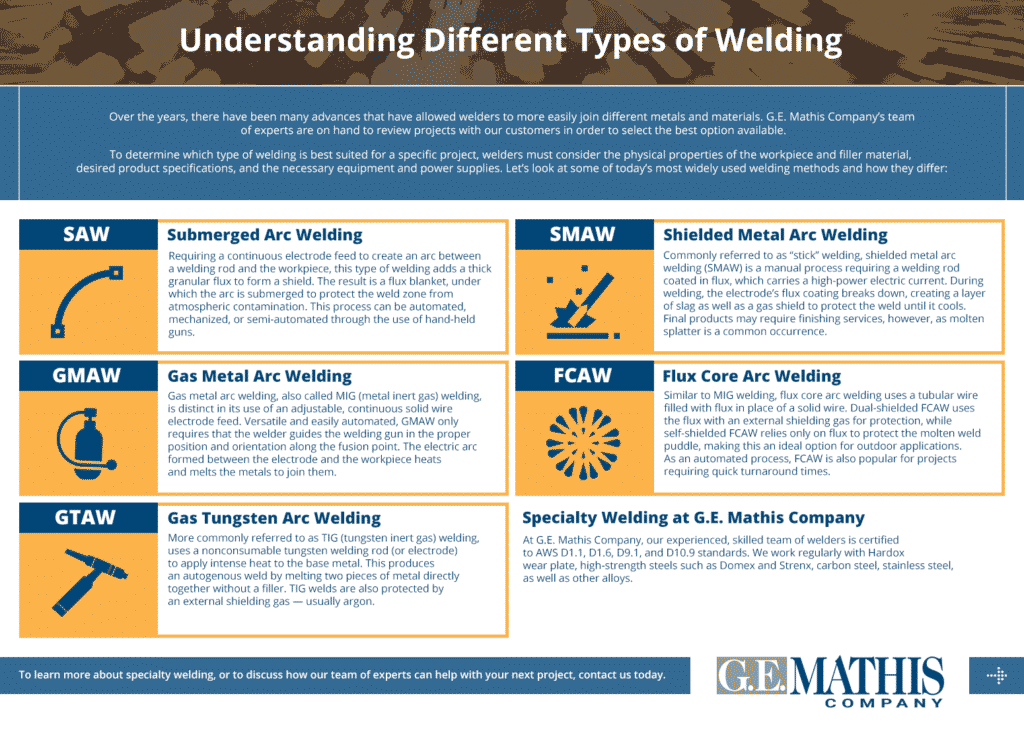

Understanding Different Types of Welding

In understanding different types of welding, and which is best suited for a specific project, one must consider many properties, applications and more. Over the years, there have been many advances that have allowed welders to more easily join different metals and materials. As specialized welding techniques are developed to better suit the needs of specific industry challenges, it may become less clear which option will be best for the job at hand. G.E. Mathis Company’s team of experts are on hand to review projects with our customers in order to select the best option available.

Let’s look at some of today’s most widely used welding methods and how they differ:

Submerged Arc Welding (SAW)

Requiring a continuous electrode feed to create an arc between a welding rod and the workpiece, this type of welding adds a thick granular flux to form a shield. The result is a flux blanket, under which the arc is submerged to protect the weld zone from atmospheric contamination. This process can be automated, mechanized, or semi-automated through the use of hand-held guns.

Shielded Metal Arc Welding (SMAW)

Commonly referred to as “stick” welding, shielded metal arc welding (SMAW) is a manual process requiring a welding rod coated in flux, which carries a high-power electric current. During welding, the electrode’s flux coating breaks down, creating a layer of slag as well as a gas shield to protect the weld until it cools. Final products may require finishing services, however, as molten splatter is a common occurrence.

Gas Metal Arc Welding (GMAW)

Gas metal arc welding, also called MIG (metal inert gas) welding, is distinct in its use of an adjustable, continuous solid wire electrode feed. Versatile and easily automated, GMAW only requires that the welder guides the welding gun in the proper position and orientation along the fusion point. The electric arc formed between the electrode and the workpiece heats and melts the metals to join them.

Flux Core Arc Welding (FCAW)

Similar to MIG welding, flux core arc welding uses a tubular wire filled with flux in place of a solid wire. Dual-shielded FCAW uses the flux with an external shielding gas for protection, while self-shielded FCAW relies only on flux to protect the molten weld puddle, making this an ideal option for outdoor applications. As an automated process, FCAW is also popular for projects requiring quick turnaround times.

Gas Tungsten Arc Welding (GTAW)

Gas tungsten arc welding, more commonly referred to as TIG (tungsten inert gas) welding, uses a non-consumable tungsten welding rod (or electrode) to apply intense heat to the base metal. This produces an autogenous weld by melting two pieces of metal directly together without a filler. TIG welds are also protected by an external shielding gas — usually argon. This method produces strong, high-quality welds, though the process can be painstaking, requiring extreme focus and precision to weld the small space between the arc and the work-piece.

Specialty Welding at G.E. Mathis Company

At G.E. Mathis Company, our experienced, skilled team of welders is certified to AWS D1.1, D1.6, D9.1, and D10.9 standards. We work regularly with HARDOX® Wearplate, high-strength steels such as STRENX®, carbon steel, stainless steel, as well as other alloys.

In addition to being an ISO 9001:2015-certified manufacturer, G.E. Mathis Company can provide the following services:

- PPAP (Production Part Approval Process) – All Levels

- FAIR (First Article Inspection Report)

- Capability Studies (Statistical Process Control)

- CMRT (Conflict Minerals Reporting Template)

To learn more about specialty welding, or to discuss how our team of experts can help with your next project, feel free to request a quote, or contact us today.

Understanding Different Types of Welding

An extremely versatile fabrication process, welding is used in nearly every industry, from agriculture and mining to construction and aerospace. Over the years, specialized welding techniques have been developed to better suit the needs of specific industry challenges, whether they involve fusing dissimilar metals or custom fabricating parts for critical-use applications.

To determine which type of welding is best suited for a specific project, welders must consider the physical properties of the workpiece and filler material, desired product specifications, necessary equipment and power supplies, and the customer’s timeframe.

Let’s look at some of today’s most widely used welding methods and how they differ:

Types of Welding

Submerged Arc Welding

Requiring a continuous electrode feed to create an arc between a welding rod and the workpiece, this type of welding adds a thick granular flux to form a shield. The result is a flux blanket, under which the arc is submerged to protect the weld zone from atmospheric contamination. This process can be automated, mechanized, or semi-automated through the use of hand-held guns.

Shielded Metal Arc Welding (SMAW)

Commonly referred to as “stick” welding, shielded metal arc welding (SMAW) is an inexpensive, manual process requiring a welding rod coated in flux, which carries a high-power electric current. During welding, the electrode’s flux coating breaks down, creating a layer of slag as well as a gas shield to protect the weld until it cools. Final products may require finishing services, however, as molten splatter is a common occurrence.

Gas Metal Arc Welding (GMAW)

Gas metal arc welding, also called MIG (metal inert gas) welding, is distinct in its use of an adjustable, continuous solid wire electrode feed. Versatile and easily automated, GMAW only requires that the welder guides the welding gun in the proper position and orientation along the fusion point. The electric arc formed between the electrode and the workpiece heats and melts the metals to join them.

Flux Core Arc Welding (FCAW)

Similar to MIG welding, flux core arc welding uses a tubular wire filled with flux in place of a solid wire. Dual-shielded FCAW uses the flux with an external shielding gas for protection, while self-shielded FCAW relies only on flux to protect the molten weld puddle, making this an ideal option for outdoor applications. As an automated process, FCAW is also popular for projects requiring quick turnaround times.

Gas Tungsten Arc Welding (GTAW)

Gas tungsten arc welding, more commonly referred to as TIG (tungsten inert gas) welding, uses a non-consumable tungsten welding rod (or electrode) to apply intense heat to the base metal. This produces an autogenous weld by melting two pieces of metal directly together without a filler. TIG welds are also protected by an external shielding gas — usually argon. This method produces strong, high-quality welds, though the process can be painstaking, requiring extreme focus and precision to weld the small space between the arc and the workpiece.

Specialty Welding at G.E. Mathis Company

At G.E. Mathis Company, our experienced, skilled team of sheet metal welders is certified to AWS D1.1, D1.6, D9.1, and D10.9 standards. We work regularly with carbon steel, stainless steel, and HARDOX® Wearplate.

In addition to being an ISO 9001:2015-certified manufacturer, G.E. Mathis Company can provide the following services:

- PPAP (Production Part Approval Process) – All Levels

- FAIR (First Article Inspection Report)

- Capability Studies (Statistical Process Control)

- CMRT (Conflict Minerals Reporting Template)

To learn more about specialty welding, or to discuss how our team of experts can help with your next project, contact us today.

Three Large-Scale Metal Components You Didn’t Know We Fabricated

G.E. Mathis Company began as a one-man operation in 1905. Since then, we have grown to occupy a 135,000 square foot facility in Chicago, IL, providing fabrication services using state-of-the-art technology. While we started small, our dedication to providing oversized components is recognized today throughout the industry.

Demanding industries rely on our knowledge, expertise, and fabrication skill to create large-scale, intricate fabrications at close tolerances. Our work encompasses jobs at every level of complexity and size.

Whether we are constructing custom roll-formed cylinders, a custom-welded boom-tube, or performing architectural laser cutting of stainless steel panels, G.E. Mathis Company construction projects are virtually limitless:

· Precision Laser-cut Architectural Panels

Our shop produced a set of intricate precision laser cut large panels. We cut each panel from A240-T304 stainless steel with our 6,000-watt laser, advancing from raw materials to fully finished, ready-to-install panels in just two weeks.

The final 91 individual architectural laser cut panels measured 0.25” thick by 63” wide by 163” tall, all of which now adorn a stunning outdoor installation.

· Rolled Cylinder Segments

Petroleum tanks require some of the industry’s largest fabrications. We partnered with an oil industry client to produce premium quality rolled steel cylinders for a tank assembly. Working from a customer-supplied print, we rolled 0.375” thick 304 stainless steel plates through our variable geometry 3-roll pinch-type plate rolling machine to produce 32 rolled segments.

After rolling, each cylinder section had a 300” interior radius through 45° and was 96” long. All 32 rolled segments arrived at their final destination within three weeks.

· Custom-welded Crane Boom

Cranes are essential for moving large-scale components; building them requires heavy-duty welded rectangular tubes. Our client needed a custom boom tube section for an enormous crane. Utilizing our submerged arc seam welder, we welded STRENX® (Domex) 100XF channels into rectangular tubes that measured ¼” thick by 18” by 20” by 240” long. After welding, we inspected each piece, and delivered them within a three week timeframe.

These pieces were noteworthy for their exceptional accuracy. Our skilled welders produced 50 of these welded boom-tubes at tolerances of ±0.125” and better.

Custom Solutions from GE Mathis

The examples above are just a sample of our precision custom products. At G.E. Mathis Company, we provide custom large-scale manufacturing for virtually every industry, including:

- Agricultural

- Architectural

- Chemical

- Construction

- Defense

- Energy

- Marine

- Mining

- Trailer / Truck body

- Contract manufacturing

- High-quality components

For more information about these projects, please see our portfolio gallery or contact one of our representatives directly today.

Welding Capabilities for the Construction Industry

Welding is instrumental to the success of a construction project. Not only is it a handy repair tool for broken and damaged machine parts, it is the mainstay of production supplying any construction endeavor with the required raw materials to progress at the desired pace.

It is undertaken by skilled operators and has to be performed according to pre-defined mandates and a set of compliance rules in order to ensure that the joints are strong and immune to jostling and rust.

WELDING, ITS IMPORTANCE AND IMPERATIVE IN CONSTRUCTION

All kinds of welding rely on generating an arc that is capable of raising the temperature of the parent material to the melting point. It is then fused with a filler metal which by rule of thumb is chosen to be structurally

stronger than the original base. Ranging from sub-merged arc to metal active gas to manual metal arc, different welding processes are leveraged at construction sites around the world to serve unique needs. Special ventures in the aerospace and naval industries have progressed to laser arc hybrid welding and electron beam technology.

An operation team manipulating welding equipment must be knowledgeable of the nuances of this technique in order to ensure the integrity of welded joints and thus by association created products. A large scale construction project is only as durable as the quality of its individual components.

Also according to the Consumer Justice Group report, welding tasked to untrained labor is an extremely hazardous proposition. Thousands of injuries occur right on-site because of careless handling of equipment or experimentation by unskilled staff.

SOME BEST PRACTICES TO KEEP IN MIND

As far as possible, complicated welding responsibilities must be left to professionals. Construction projects call for the employment of AWS (American Welding Society) certified welders who are cognizant of the involved risks and capable of handling them expertly.

Especially for the frequently used MIG (Metal Inert Gas) welding:

- Care should be taken to ensure that welders wear protective gear (including an auto-darkening face shield) to eliminate the riskofcontact burns and blisters

- Cotton is the chosen material because it doesn’t melt like polyester

- Be on the look-out for splatters of molten metal and grinding sparks which can cause a fire

- Avoid using galvanized steel as the parent material since it gives off carcinogenic vapors

G.E. MATHIS COMPANY AND ITS HISTORY OF EXCELLENCE:

G.E. Mathis Company has been an industry renowned name in the field of precision arc and MIG welding. We have perfected our craft over 100 years of rigorous practice assisting construction companies, OEMs, independent projects and manufacturers with their welding and rolling needs. ISO 9001:2015 certified, we are the gold standard in the welding and precision services domain.

Feel free to request a quote, or contact us today at 773.586.3800 and we will be glad to discuss how our fabrication and welding capabilities may help with your next project

Fusion Welds:

Fusion Welds: