All About Metal Fabrication

Welding Types 101: Differences, Benefits, & Applications

Precision welding processes use carefully controlled heat and pressure to reliably fuse metal parts together and create durable joints. Welding is an ideal fabrication technique for assemblies that need inconspicuous weld lines or require close dimensional tolerances. Numerous precision welding methods are available to fulfill the needs of diverse projects, and each type offers its own unique advantages and drawbacks. Read on to learn more about the various types of precision welding, the pros and cons of welding techniques, and common applications.

Different Types of Welding Techniques

Depending on your application’s requirements, you can choose from numerous different types of welding techniques to generate reliable, high-quality welds.

Submerged Arc Welding (SAW)

A highly common welding technique, SAW creates an electrical arc between a workpiece and a continuously fed consumable electrode as well as a flux blanket. Producing welds of exceptional quality while decreasing the likelihood of distortion, this process is compatible with automation solutions, larger projects, and thick metals. However, it necessitates using specialized equipment, requires that you remove post-weld slag, and offers you limited visibility during the process.

Seam Welding

Instead of rods, this welding process utilizes wheels as electrodes to create a continuous seam in your assembly. Seam welding encompasses both friction and resistance seam welding. It’s advantageous for its ability to produce quick yet durable joints with minimal overlapping, heat distortion, and pollution. The process is a good choice for gas- or liquid-tight vessels, but it’s not the right option for metals exceeding 3mm in thickness. The specialized equipment capable of seam welding is also quite costly and requires a highly skilled operator.

Shielded Metal Arc Welding (SMAW)

Called simply arc welding and stick welding as well, the versatile SMAW method generates an electrical arc with a consumable electrode protected by a flux shield. The process doesn’t rely on shielding gas. Equipment for the SMAW technique is both portable and economical, and it’s well-suited to a range of material options as long as they aren’t too thin. However, the SMAW method is slowgoing, and the weld quality relies solely on your operator’s skill. You must also remove slag upon completion.

Gas Metal Arc Welding (GMAW)

Also referred to as metal inert gas (MIG) welding, GMAW shields an electrode of solid wire construction with an external gas supply to safeguard against reactive environmental conditions. Unlike SMAW, this technique is applicable for thinner metals — as long as they’re ferrous —and doesn’t require as high a degree of welding talent to generate welds of superior quality. Another of the advantages of MIG welding is that it allows for faster rates of deposition. With this technique, keep in mind that it does necessitate using a shielding gas, and you might experience wire-feeding complications.

Gas Tungsten Arc Welding (GTAW)

Also known as tungsten inert gas (TIG) welding, this technique protects its non-consumable electrode of tungsten material utilizing an inert shielding gas. The advantages of TIG welding include its ability to create precise, clean, and high-quality welds. Compared to some other welding techniques, it emits less fumes and smoke, and it also works well with a broad spectrum of metals and alloy materials. However, the process is time-intensive and requires a well-trained operator and costly equipment to achieve.

Flux Core Arc Welding (FCAW)

Best for thicker metals, FCAW protects the electrode with core-provided gas rather than external gas like MIG welding. It possesses a higher production factor than GTAW or SMAW methods, and FCAW is beneficial for its high rate of deposition and efficiency. That said, it’s less precise than GTAW and increases your risk of lack of fusion in your project. The process requires shielding gas to work, as well as slag removal post-weld. There are two types of flux core welding: One shielded with an inert gas and one that does not require gas.

Common Welding Applications

The benefits of welding lend it to applications across a wide range of industries, including:

- Aerospace. Precision welding allows operators to generate welds on air- and spacecraft parts, enabling them to achieve tight tolerances for mission-critical components.

- Agriculture. This sector requires rugged equipment, and welded components offer that durability as part of tractors, plows, harvesters, backhoes, balers, sprayers, and more.

- Construction. Precision welding is essential for creating structurally sound welded joints on steel I-beams, support pilings, railings, and general load-bearing components and equipment parts.

- Contract manufacturing. Both manufactured components and manufacturing equipment require precision welding to create lasting, industrial-strength bonds.

- Military. Precision welding is effective at providing assemblies for transport vehicles, trucks, vehicle components, communication tools, process armor kits, submarines, and ships.

- Mining. Examples of fabricated components and welded assemblies for mining equipment include elevators, mine cages and cars, conveyor belts, ore pass chutes, skips, and drifts.

Precision Welding Services From G.E. Mathis Company

Precision Welding Services From G.E. Mathis Company

G.E. Mathis Company leverages over a century of extensive experience and multi-industry expertise to maximize customer success. At every stage of operations, we maintain the highest level of craftsmanship, product quality, and integrity for even the largest of welding projects. Our company is ISO 9001:2015 and AWS-D1.1 certified, and we have a Certified Welding Inspector (CWI) on our team to ensure consistent weld quality with some of the tightest tolerances in the industry.

Our precision welding processes incorporate computer numerical control (CNC) and automated welding systems for maximum efficiency and accuracy. We work with varied material grades and types ranging from stainless and carbon steel to aluminum and HARDOX® wearplate, creating lasting welds on products up to 50 feet in length and 12 feet in width.

Along with extensive precision welding techniques, our experienced technicians are fully adept at the following value-added services, which we handle in-house at our fully equipped, state-of-the-art facility:

- Custom metal fabrication

- CNC laser cutting

- Press-brake forming

- Non-destructive testing (NDT) and dimensional inspections

- Kitting and packaging

- Production Part Approval Process (PPAP) at all levels

- First Article Inspection Report (FAIR)

- Capability Studies (Statistical Process Control)

- Conflict Minerals Reporting Template (CMRT)

- Galvanizing and painting

Offering turnkey service capabilities allows us to meet your expectations for quality products, shorter lead times, and competitive pricing. Contact us to learn more about our precision welding services, or request a quote today to discuss your metalworking needs.

First Article Inspection Reports 101 – What is FAI / FAIR

Mass production of products within the aerospace and defense industries requires an initial inspection known as the First Article Inspection (FAI) and a report on the results. G.E. Mathis Company is committed to providing the highest quality inspections and reports that comply with the AS9102 standards to ensure that products meet the correct specifications during manufacturing.

What is First Article Inspection?

At the beginning of a production run, all business quality systems provide a report of the inspection of one to five products straight off the manufacturing line. Regardless of whether the system is certified to ISO 9001, TS16949, or AS9102 standards, quality inspection for compliance with the documentation or customer requirements must be completed before the production run continues. Included in the review are the measurements of the layout to ensure conformity.

Other testing may include material tests and reports, appearance approvals, and more. Once all documents are received, the First Article Inspection Report (FAIR) provides the customer with a review of the product and sets the expectation for the outcome of the full production run. Customers indicate how many parts, between one and five, require inspection in the FAI before approval to continue the run.

First Article Inspection Reports (FAIR)

A First Article Inspection Report (FAIR) can be requested during a mass production run to ensure consistent product quality. However, the FAIR process typically begins by validating the manufacturing processes and the associated equipment, including when:

- Introducing New Parts

- Revising Existing Parts

- New Locations for Manufacturing

- New Supplier of Parts

- Resuming manufacturing after two years

Each FAIR has three forms that must meet the expectations outlined in the documentation. The forms include the part number accountability, product accountability, and characteristic accountability inspection forms. Two forms of inspection are carried out to ensure quality control and product reliability. The first form is dedicated to identifying the part that requires review, along with any sub-assemblies that may affect the quality of the final product. This form helps to ensure that quality issues are identified and resolved at the earliest stages of production.

The second form, product accountability, is a more comprehensive inspection process that covers all related materials, methods, and functional tests demanded by the product design. This form is crucial in ensuring that all product components function correctly and meet the required specifications. By conducting this inspection, any potential defects or issues that may arise during the product’s use can be identified and addressed, resulting in a more reliable and long-lasting product.

Finally, the characteristic accountability inspection ensures that the characteristics, dimensions, tolerances, and aesthetics align with the customer’s specifications. This form includes a detailed drawing or model pinpointing the necessary features identifiable by ballooned or bubbled numbers. A key provides details on the numbered aspects of the picture. The tools used to produce the product are included in the inspection for quality at this time.

Choosing G.E. Mathis Company for Your FAIR

Parts manufacturing is becoming more complex as the parts themselves evolve. Ensuring that each piece manufactured complies with all specified restrictions and requirements is essential to ensure products are successful after assembly. Completing a FAIR inspection during the manufacturing process ensures compliance with regulations and provides clients with product details.

Quality, integrity, and craftsmanship are at the forefront of our values at G.E. Mathis Company. Our dedication to our customers’ success is unwavering, and we strive to uphold these principles in everything we do. In addition to being an ISO 9001:2015-certified manufacturer, G.E. Mathis Company can provide the following services:

- FAIR (First Article Inspection Report)

- PPAP (Production Part Approval Process) – All Levels

- Capability Studies (Statistical Process Control)

- CMRT (Conflict Minerals Reporting Template)

Don’t hesitate to contact us today to learn more about G.E. Mathis Company and how we can apply our metal fabrication capabilities to your next project. Request a quote for your project or FAI assignment and get the expert help your facility deserves.

4 Tips for Designing Large, Cost-Effective Components

Large parts are often challenging to fabricate; making cost-effective decisions during the design stage can help to ensure manufacturing success. Sometimes a small change in a design can reduce a project’s cost substantially.

1. Make Things Easy

Easy-to-read drawings take the guesswork out of fabricating. As this is often the only thing that the shop has to work with, it is important to make sure your information is clear, so your manufacturer understands all of the details of the part they are creating.

2. Provide Context

Clearly communicate how you plan to use the final product. Experienced metalworkers will be better equipped to take on your large component fabrication project if they understand the part’s intended use.

All technical drawings and documents should include these details and provide vital information to manufacturers and help them to choose the best equipment for cost-effective fabrication.

3. Be Consistent

Legibility is important, but drawings and prints must also provide consistent and clear information. In-depth data is more important than exact scale drawings and will ensure the best accuracy.

Every drawing should convey the dimensions and tolerances of the product, with clear labeling that identifies all required materials and finishes.

4. Be Conscientious

If you’re not sure what processes will be used, like laser cutting, we’ll be happy to talk to you about it. We will gladly work with you towards a solution.

Your Partner in Large Scale Manufacturing

By following these guidelines, your designs will be easily fulfilled to suit all of your application’s requirements. At G.E. Mathis Company, we do our part by maintaining the tooling, equipment, and expertise to complete precision welding fabrication projects of virtually any size.

In addition to being an ISO 9001:2015-certified manufacturer, G.E. Mathis Company can provide the following services:

- PPAP (Production Part Approval Process) – All Levels

- FAIR (First Article Inspection Report)

- Capability Studies (Statistical Process Control)

- CMRT (Conflict Minerals Reporting Template)

For further information, contact us today or request a quote for your next project.

The Versatility of HARDOX® Wearplate

Specifically designed for use in harsh, demanding applications, HARDOX® Wearplate provides an unmatched combination of hardness and toughness, allowing for extended service life and cost savings. This unique material is used across a wide range of industries to provide optimal reliability and wear resistance.

Why Is HARDOX® So Tough?

HARDOX® Wearplate is a wear-resistant sheet steel developed by the Swedish company SSAB in 1974. This steel wears slowly, allowing the equipment used in abrasive applications and aggressive-wear environments to last longer, thereby reducing maintenance needs and costs.

HARDOX® offers a unique combination of hardness, strength, and toughness. The material’s high strength enables thinner metal sheets to be used, meaning products can be made to be simpler and lighter while still carrying high payloads. HARDOX® Wear Plate also has good impact resistance, even at low temperatures.

HARDOX® sheets and plates provide ideal welding and machining properties, simplifying production and repair work. To provide this excellent weldability, HARDOX® Wear Plate steel is manufactured to have a highly accurate chemical composition. Advanced hardening and post-treatment processes also help imbue it with its unique properties. The combination of high payloads, low maintenance costs, good availability, and long service life allows for overall cost savings while ensuring optimal reliability.

Finally, HARDOX® provides superior wear performance, crack safety, and deformation resistance provide defense against wear, dents, and cracks. To evaluate these properties, HARDOX® and ordinary high strength structural plates have been compared through comprehensive drop tests; in one test, weights varied between 330 and 1,800 pounds and were dropped from heights of up to 10 feet. The HARDOX® steel plate showed only moderate deformation, while the structural steel alternative couldn’t withstand the impact.

Advantages of HARDOX®

Extremely versatile, HARDOX® provides critical benefits for various industries. Below are some of the key features discussed above.

- Superior hardness — Offering excellent wear resistance, HARDOX® features all-around hardness that doesn’t impact structural performance.

- Excellent toughness — HARDOX® is able to resist cracks if subjected to deformation and can withstand heavy blows, allowing it to be easily bent, formed, and welded. Combined with its high yield strength, this durability also allows for the creation of lightweight designs.

- Consistency — HARDOX® retains its properties and strength even in severe, harsh conditions — and also during precision bending and forming, as well as precision welding and MIG welding — allowing for predictable, reliable results.

- Long service life — HARDOX® can double, or even triple, equipment wear plate service life, optimizing performance while minimizing the risk of damage.

Common HARDOX® Applications

HARDOX® unique properties make it well suited to a wide range of industries and applications, such as:

- Construction and demolition — HARDOX® can be used in various types of construction equipment, from evacuators and demolition tools to fragmentizers, all of which require high reliability and longevity to withstand heavy use and ensure worker safety.

- Mining — In this safety-critical industry, worker’s equipment — such as mining trucks — must be able to stand up to harsh conditions while maintaining a long lifespan; HARDOX® provides this reliability, cutting down on repair costs and delays.

- Military — HARDOX® Wear Plate provides the protective strength and reliability required in the military industry and is commonly used in the manufacture of armored vehicles.

STRENX® (Domex® ): High Performance, High Strength Steel

What Is STRENX®?

STRENX® is a High Strength, hot-rolled steel sheet also offered by SSAB; the steel is low-alloy and cold-formed. Previously called Domex, this unique material has been rebranded as STRENX.

The Advantages of STRENX®

Extremely versatile, STRENX® provides critical advantages for various industries. Some of its unique qualities and benefits include:

- Excellent versatility — This steel has excellent formability and good weldability, meaning it can undergo various manufacturing processes.

- Reduced production costs — Strenx allows for the manufacture of stronger, higher-quality products that require less steel and welding. This also allows for a lighter-weight product less susceptible to damage, saving money on repair and replacement costs in the long run.

Common STRENX® (Domex) Applications

The unique properties of STRENX® make it well-suited to a wide range of industries and applications, such as:

- Automotive — Designers like to keep structural weight low but strength-handling levels high. With Strenx, products made can be simpler and lighter while still carrying higher payloads.

- Construction and demolition — Strenx can be used in cranes and booms, both of which require high reliability and longevity to withstand heavy use and ensure optimal worker safety.

Learn More

To learn more about the uses and unique properties of HARDOX® — which is ideal for a wide range of fabrication methods, including welding, cutting, bending, and bending — download our free eBook, “Fabricating Tougher Components with HARDOX® Wearparts.”

Understanding Different Types of Welding

An extremely versatile fabrication process, welding is used in nearly every industry, from agriculture and mining to construction and aerospace. Over the years, specialized welding techniques have been developed to better suit the needs of specific industry challenges, whether they involve fusing dissimilar metals or custom fabricating parts for critical-use applications.

To determine which type of welding is best suited for a specific project, welders must consider the physical properties of the workpiece and filler material, desired product specifications, necessary equipment and power supplies, and the customer’s timeframe.

Let’s look at some of today’s most widely used welding methods and how they differ:

Types of Welding

Submerged Arc Welding

Requiring a continuous electrode feed to create an arc between a welding rod and the workpiece, this type of welding adds a thick granular flux to form a shield. The result is a flux blanket, under which the arc is submerged to protect the weld zone from atmospheric contamination. This process can be automated, mechanized, or semi-automated through the use of hand-held guns.

Shielded Metal Arc Welding (SMAW)

Commonly referred to as “stick” welding, shielded metal arc welding (SMAW) is an inexpensive, manual process requiring a welding rod coated in flux, which carries a high-power electric current. During welding, the electrode’s flux coating breaks down, creating a layer of slag as well as a gas shield to protect the weld until it cools. Final products may require finishing services, however, as molten splatter is a common occurrence.

Gas Metal Arc Welding (GMAW)

Gas metal arc welding, also called MIG (metal inert gas) welding, is distinct in its use of an adjustable, continuous solid wire electrode feed. Versatile and easily automated, GMAW only requires that the welder guides the welding gun in the proper position and orientation along the fusion point. The electric arc formed between the electrode and the workpiece heats and melts the metals to join them.

Flux Core Arc Welding (FCAW)

Similar to MIG welding, flux core arc welding uses a tubular wire filled with flux in place of a solid wire. Dual-shielded FCAW uses the flux with an external shielding gas for protection, while self-shielded FCAW relies only on flux to protect the molten weld puddle, making this an ideal option for outdoor applications. As an automated process, FCAW is also popular for projects requiring quick turnaround times.

Gas Tungsten Arc Welding (GTAW)

Gas tungsten arc welding, more commonly referred to as TIG (tungsten inert gas) welding, uses a non-consumable tungsten welding rod (or electrode) to apply intense heat to the base metal. This produces an autogenous weld by melting two pieces of metal directly together without a filler. TIG welds are also protected by an external shielding gas — usually argon. This method produces strong, high-quality welds, though the process can be painstaking, requiring extreme focus and precision to weld the small space between the arc and the workpiece.

Specialty Welding at G.E. Mathis Company

At G.E. Mathis Company, our experienced, skilled team of sheet metal welders is certified to AWS D1.1, D1.6, D9.1, and D10.9 standards. We work regularly with carbon steel, stainless steel, and HARDOX® Wearplate.

In addition to being an ISO 9001:2015-certified manufacturer, G.E. Mathis Company can provide the following services:

- PPAP (Production Part Approval Process) – All Levels

- FAIR (First Article Inspection Report)

- Capability Studies (Statistical Process Control)

- CMRT (Conflict Minerals Reporting Template)

To learn more about specialty welding, or to discuss how our team of experts can help with your next project, contact us today.

New Website for G.E. Mathis Company

G.E. Mathis Company recently launched a new website. This new site is completely redesigned from top to bottom. In addition to easier access and a totally new design, what else can you expect when you visit G.E. Mathis Company’s brand new website?

Here’s an overview of the latest updates:

1. Improved accessibility

Our new drop-down navigation menu makes it easier to browse our valuable resources and company information. The navigation menu is conveniently located at the top of each page. Users can easily access our services, industries, case studies, photo gallery, and more.

2. More user-friendly experience

With over a century’s worth of experience, we at G.E. Mathis Company pride ourselves on delivering quality services and capabilities to our customers. With that in mind, we’ve ensured that our new website offers the best possible user experience. We’ve achieved this goal by implementing a completely new and more appealing design. We have also given the site a responsive design. This makes it simple to access our site on any desktop, tablet or mobile device.

3. Enhanced information

We know when users visit a website, they want to find relevant information quickly and easily. Our new website highlights past projects we’ve successfully completed by showcasing them in our portfolios. These feature jobs in laser cutting, forming, plasma cutting, and welding. We also provide the most up-to-date information on all of the services we offer, including:

- Laser Processing

- High-Def CNC Plasma Cutting

- Precision Forming/Bending

- Welding

- HARDOX® Wearparts Fabrication

In addition to being an ISO 9001:2015-certified manufacturer, G.E. Mathis Company can provide the following services:

- PPAP (Production Part Approval Process) – All Levels

- FAIR (First Article Inspection Report)

- Capability Studies (Statistical Process Control)

- CMRT (Conflict Minerals Reporting Template)

We encourage you to browse our new website today to learn more about the intricate and close-tolerance fabrication services we provide. These cover a vast range of industries from construction, agricultural, chemical, defense, mining, trailers/truck bodies, contract manufacturing, and much more. You can also always request a quote, or contact us with any questions or learn how we can assist you with your next project.

Three Large-Scale Metal Components You Didn’t Know We Fabricated

G.E. Mathis Company began as a one-man operation in 1905. Since then, we have grown to occupy a 135,000 square foot facility in Chicago, IL, providing fabrication services using state-of-the-art technology. While we started small, our dedication to providing oversized components is recognized today throughout the industry.

Demanding industries rely on our knowledge, expertise, and fabrication skill to create large-scale, intricate fabrications at close tolerances. Our work encompasses jobs at every level of complexity and size.

Whether we are constructing custom roll-formed cylinders, a custom-welded boom-tube, or performing architectural laser cutting of stainless steel panels, G.E. Mathis Company construction projects are virtually limitless:

· Precision Laser-cut Architectural Panels

Our shop produced a set of intricate precision laser cut large panels. We cut each panel from A240-T304 stainless steel with our 6,000-watt laser, advancing from raw materials to fully finished, ready-to-install panels in just two weeks.

The final 91 individual architectural laser cut panels measured 0.25” thick by 63” wide by 163” tall, all of which now adorn a stunning outdoor installation.

· Rolled Cylinder Segments

Petroleum tanks require some of the industry’s largest fabrications. We partnered with an oil industry client to produce premium quality rolled steel cylinders for a tank assembly. Working from a customer-supplied print, we rolled 0.375” thick 304 stainless steel plates through our variable geometry 3-roll pinch-type plate rolling machine to produce 32 rolled segments.

After rolling, each cylinder section had a 300” interior radius through 45° and was 96” long. All 32 rolled segments arrived at their final destination within three weeks.

· Custom-welded Crane Boom

Cranes are essential for moving large-scale components; building them requires heavy-duty welded rectangular tubes. Our client needed a custom boom tube section for an enormous crane. Utilizing our submerged arc seam welder, we welded STRENX® (Domex) 100XF channels into rectangular tubes that measured ¼” thick by 18” by 20” by 240” long. After welding, we inspected each piece, and delivered them within a three week timeframe.

These pieces were noteworthy for their exceptional accuracy. Our skilled welders produced 50 of these welded boom-tubes at tolerances of ±0.125” and better.

Custom Solutions from GE Mathis

The examples above are just a sample of our precision custom products. At G.E. Mathis Company, we provide custom large-scale manufacturing for virtually every industry, including:

- Agricultural

- Architectural

- Chemical

- Construction

- Defense

- Energy

- Marine

- Mining

- Trailer / Truck body

- Contract manufacturing

- High-quality components

For more information about these projects, please see our portfolio gallery or contact one of our representatives directly today.

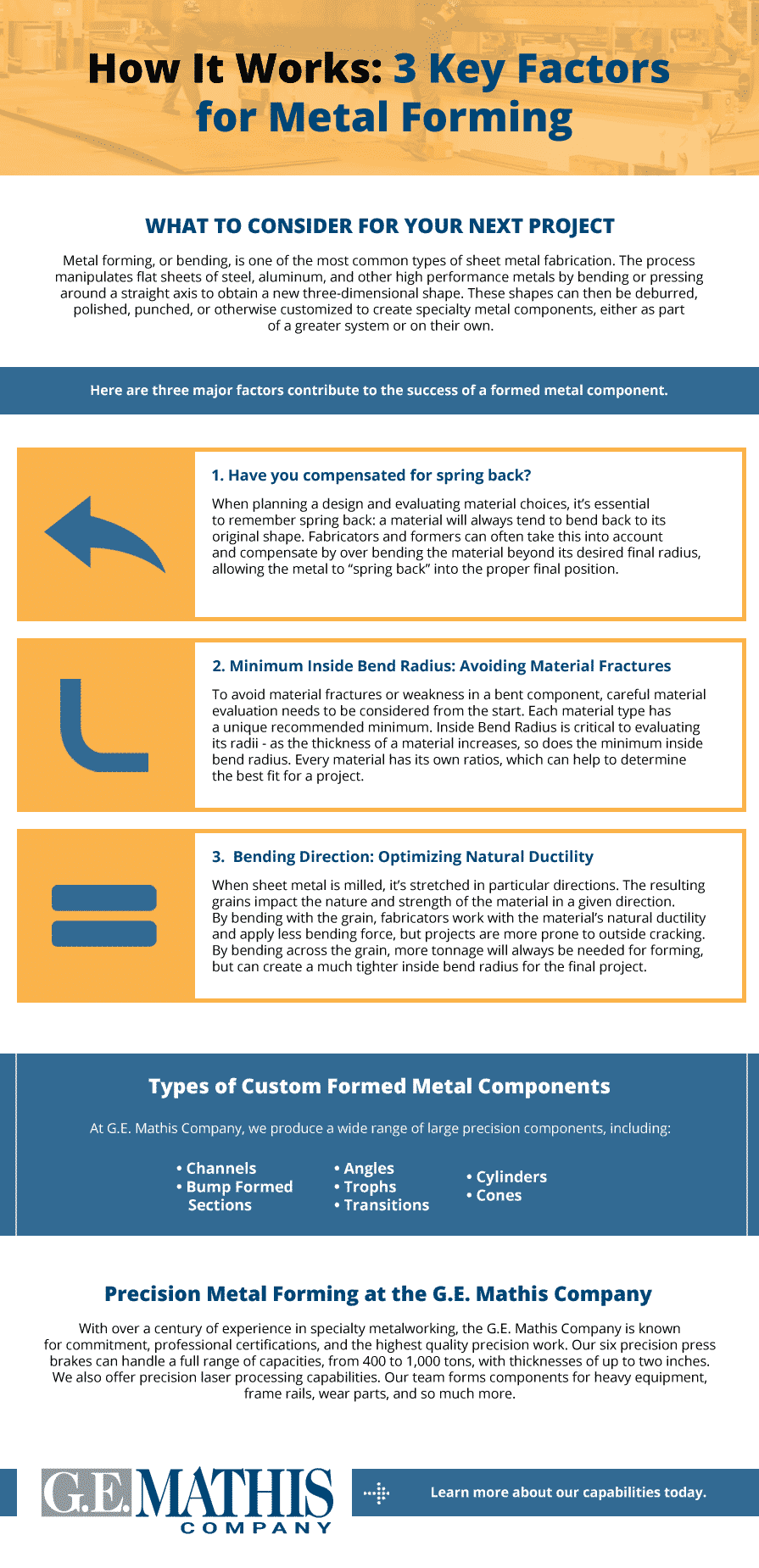

How It Works: 3 Key Factors for Metal Forming

What to Consider for Your Next Project

Metal forming, or bending, is one of the most common types of metal fabrication. The process manipulates flat sheets of steel, aluminum, and other high performance metals by bending or pressing around a straight axis to obtain a new three-dimensional shape. These shapes can then be deburred, polished, or otherwise customized to create specialty metal components, either as part of a greater system or on their own.

Here are three major factors contribute to the success of a formed metal component.

1. Have you compensated for spring back?

When planning a design and evaluating material choices, it’s essential to remember spring back: a material will always tend to bend back to its original shape. Fabricators can often take this into account and compensate by over bending the material beyond its desired final radius, allowing the metal to “spring back” into the proper final position.

2. Minimum Inside Bend Radius: Avoiding Material Fractures

To avoid material fractures or weakness in a bent component, careful material evaluation needs to be considered from the start. Each material type has a unique recommended minimum. Inside Bend Radius is critical to evaluating its radii — as the thickness of a material increases, so does the minimum inside bend radius. Every material has its own ratios, which can help to determine the best fit for a project.

3. Bending Direction: Optimizing Natural Ductility

When sheet metal is milled, it’s stretched in particular directions. The resulting grains impact the nature and strength of the material in a given direction, so be sure to note whether a sheet is being formed with (longitudinally) or across the grain.

By bending with the grain, fabricators work with the material’s natural ductility and apply less bending force, but projects are more prone to outside cracking. By bending across the grain, more tonnage will always be needed for forming, but can create a much tighter inside bend radius for the final project.

Types of Custom Formed Metal Components

Metal forming specialists craft the critical components needed to support almost every industry — aerospace, military, automotive, medical, food service, manufacturing, communications — the list goes on and on. At G.E. Mathis Company, we produce a wide range of large precision components, including:

- Channels

- Angles

- Formed Pan sections

- Transition segments

- Bump Formed Sections

- Cones

Precision Metal Forming at the G.E. Mathis Company

With over a century of experience in specialty metalworking, the G.E. Mathis Company is known for commitment, professional certifications, and the highest quality precision work. Our eight precision press brakes can handle a full range of capacities, from 400 to 1,000 tons, with thicknesses of up to two inches. We offer metal fabrication beyond bending and forming, too — precision laser processing, plasma cutting, and welding are a few of our capabilities.

Our team forms components for heavy equipment, frame rails, wear parts, and so much more. Contact us to discuss your next project with one of our metal forming professionals or learn more about our capabilities today.

American Manufacturing in 2014 and the Outlook for 2015

Pundits are attributing this ‘revival’ of US manufacturing to three main reasons:

- Because of the sophistication of the fracking process, the US is now the largest producer of oil and natural gas in the world, trumping Saudi Arabia to claim the elusive title. The implications of this feat are profound leading to a significant drop in transportation as well as electric costs within the country.

- Because of the innovations in the field of robotics, the rote work of wrench turning has now been delegated to industrial robots and other precision instruments. The main issue with labor in the US was availability of reliable and competent blue collar workers for the minimum wage rate. Thanks to the automation of certain processes, human ingenuity and logic can be better rewarded with higher paying jobs of supervisors and managers.

- United States can now boast very low cost of raw materials leading to a dip in overall manufacturing investment as well.

The US manufacturing sector alone is the 8th largest economy in the world, and this trend is likely to sustain in 2015 and even beyond.

The main focus of the coming years is going to be the Re-shoring vs. Offshoring battle. The global labor pool has become more aware of its rights, and the cry of improved wages is resonating from all corners of the world. Pay has risen by a significant 10% in China and were likely to spread to other countries as well.

Most probably the industries which are not labor intensive and suffer from the often prohibitive costs of long transportation routes (like chemicals and metals) will move back to home soil in order to take advantage of the boom in oil production and the easily available rich reserves of raw materials.

Ventures with high foreign demand and the pressing need for a lot of affordable labor to keep production running will continue to go the offshore way, especially if the manufacturing skill gap is not remedied.

The future of US Manufacturing is bright! But only time can shed light on the dominant trends which will re-shape the sector for the coming decades.

Precision Welding Services From G.E. Mathis Company

Precision Welding Services From G.E. Mathis Company