What Industries Use Laser Cutting?

When fabricating components from metal, there are a number of processes that might be suitable. The best method will vary depending on factors such as the type of metal involved and the application’s unique demands. However, laser cutting offers a number of benefits that make it a popular fabrication technique for many industries. This blog post will discuss how laser cutting works and which industries heavily rely on it.

What Is Laser Cutting?

Laser cutting is the process of cutting through metal materials using a focused, high-powered beam of light. It is a highly precise thermal process often recommended in applications requiring tight tolerances, precise cutouts, or holes that are small in relation to the material thickness. This cutting process is ideally suited for many applications.

Lasers can cut through metals such as aluminum, stainless steel, and other mild steels with only a small kerf (the material width removed by a cutting process), producing no other damage to the material. Stainless steel laser cutting, in particular, is a popular fabrication process due to the many benefits it provides. Some of the most notable laser cutting advantages include:

- Limited to no physical contact during the cutting process

- Increased worker safety over hand-held cutting methods

- Suitable for a broad range of metal types

- A single laser machine cuts through many types of me

- tal

- Significantly higher cutting precision and tighter tolerances than other methods, such as plasma cutting

Industries that Use Laser Cutting

The versatility of the laser cutting process along with the high degree of precision it provides has led it to be a popular fabrication process in a number of industries. Let’s take a closer look at some of the key industries that rely on laser cutting and how the process is used within those applications.

Agricultural

Laser cutting is a critical process for the agricultural industry, where it is used to produce components for many types of machinery. Equipment such as spreaders, chassis, grain movement components, and tractors are all fabricated using laser cut component parts. In agricultural applications, this process is used to produce most two-dimensional shapes and provides extensive shape production abilities.

Contract Manufacturing

The versatility of laser cutting makes it essential to the contract manufacturing industry, as it can produce components from many different materials in various shapes. The flexibility of laser cutting has made it integral to quickly produce prototype parts, and the accuracy of the laser lends itself to product consistency through repeatability during production runs.

Military

Components used in military applications must meet unique specifications and follow stringent government regulations due to the challenging environments in which they are used. Laser cutting provides the accuracy and reliability necessary to meet these demands and is used to produce a wide variety of components used throughout all branches of the military.

Construction

Laser cutting provides effective, modern solutions for metal part production within construction applications and is transforming the industry. Increasingly, companies are choosing laser cutting fabrication due to its ability to improve production speed and increase operational control and efficiency. Laser cutting is used to produce truck parts, boom tube sections for cranes, and many other components.

G.E. Mathis Company: Reliable Precision Laser Cutting Services

The advantages laser cutting provides over other traditional fabrication techniques have led it to become an essential fabrication method for many industries. For projects involving many types of metal, laser cutting delivers unmatched precision and handles even highly complex designs accurately. In comparison to other metal fabrication techniques, laser cutting reduces lead times and waste materials and can easily accommodate high production volumes.

G.E. Mathis Company specializes in precision laser cutting for demanding industries. Using highly advanced equipment and our 135,000 square-foot production facility, we deliver components tailored to our customers’ exact specifications.

In addition to being an ISO 9001:2015-certified manufacturer, G.E. Mathis Company can provide the following services:

- PPAP (Production Part Approval Process) – All Levels

- FAIR (First Article Inspection Report)

- Capability Studies (Statistical Process Control)

- CMRT (Conflict Minerals Reporting Template)

To learn more about our laser cutting services, contact us today. When you’re ready to get started on a solution, request a quote.

How Does Laser Cutting Work?

Lasers come in a wide array of types and strengths, producing extremely accurate cuts that facilitate the creation of intricate shapes. This thermal cutting process is favored for a variety of applications and particularly useful with soft and mild metals that are prone to excess damage from more traditional cutting tools. Lasers can cut through mild steel, stainless steels and aluminum with only a small kerf without otherwise damaging the remaining material.

This article will describe the laser cutting process and how it works.

What is a Laser?

Though the full term is rarely used anymore, the word “LASER” is an acronym for Light Amplification by Stimulated Emission of Radiation. This form of light doesn’t exist in nature and was artificially created to harness the unique properties of light in a controllable device. Lasers vary in light type, intensity, and diameter to facilitate uses across a wide variety of recreational, commercial, and industrial applications.

Each laser beam is a collection of light beams with identical or nearly identical wavelengths. The waves are in phase, which means they travel uniformly with the peaks of each wave occurring in sync. This manipulation of the light waves gives a laser its signature brightness and narrow focus. This focus produces very uniform light that will travel long distances. Laser beams also concentrate energy, or power, into a small surface area.

The Laser Cutting Process

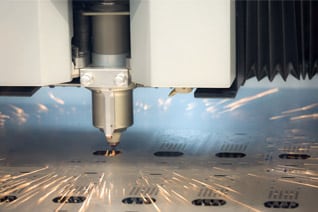

Concentrated energy is the core premise of laser cutting. Laser cutting machines generate a ¾-inch wide laser beam. This beam is pushed through a nozzle, which contains compressed oxygen, nitrogen, or another gas, and potentially through beam bender mirrors.

Laser cutting machines use precise setups to focus the beam within the laser cutting head. First, a curved mirror or lens concentrates the light into a single point. At this point, the light is concentrated, small, and produces significant heat. The laser cutting head’s focus concentrates the laser beam until it’s strong enough to melt through metal. It heats, melts, and vaporizes the material along its cut path.

The process may differ depending on the type of metal being cut:

- Mild steel cutting uses pure oxygen in the nozzle bore. The laser’s heat triggers an oxy-fuel burn with pure oxygen.

- Aluminum or stainless steel cutting uses pure nitrogen in the nozzle bore. The laser handles all the burning and cutting, while the nitrogen blows the kerf free of molten metal remains.

Laser cutters carefully orient the laser cutting head to facilitate the melting and cutting action. If the focal point is even slightly too low or too high, it can alter the quality of the cut. Precision aiming is facilitated using a capacitive height control system. The cutting head follows programmed instructions to create specific cuts and holes according to design specifications.

Materials for Laser Cutting

Lasers can etch and cut through many different materials. At G.E. Mathis Company, we work with the following materials:

- Aluminum

- Carbon steel

- High-strength steel

- Abrasion Resistant Steel

- Stainless steel

G.E. Mathis Company Precision Laser Cutting

G.E. Mathis Company specializes in high-quality laser cutting and etching for prototype, low-volume, and high-volume orders. Our advanced equipment and skilled laser technicians can handle a broad range of materials, product dimensions, material thicknesses, and order volumes. Our standard thickness capabilities range from 16-gauge sheet metal to steel plates 1-1/4 inches thick.

In addition to being an ISO 9001:2015-certified manufacturer, G.E. Mathis Company can provide the following services:

- PPAP (Production Part Approval Process) – All Levels

- FAIR (First Article Inspection Report)

- Capability Studies (Statistical Process Control)

- CMRT (Conflict Minerals Reporting Template)

To see how our laser cutting capabilities can serve your project, please contact us or request a quote.

Laser Cutting Stainless Steel vs. Plasma Cutting

Should I use Laser cutting or should I use Plasma cutting?

This is a common question that customers ask us. They want to know the difference between the two, and which cutting process is better suited for their application or end-use. While the answer is not always cut and dry, there are some general rules that separate the two processes.

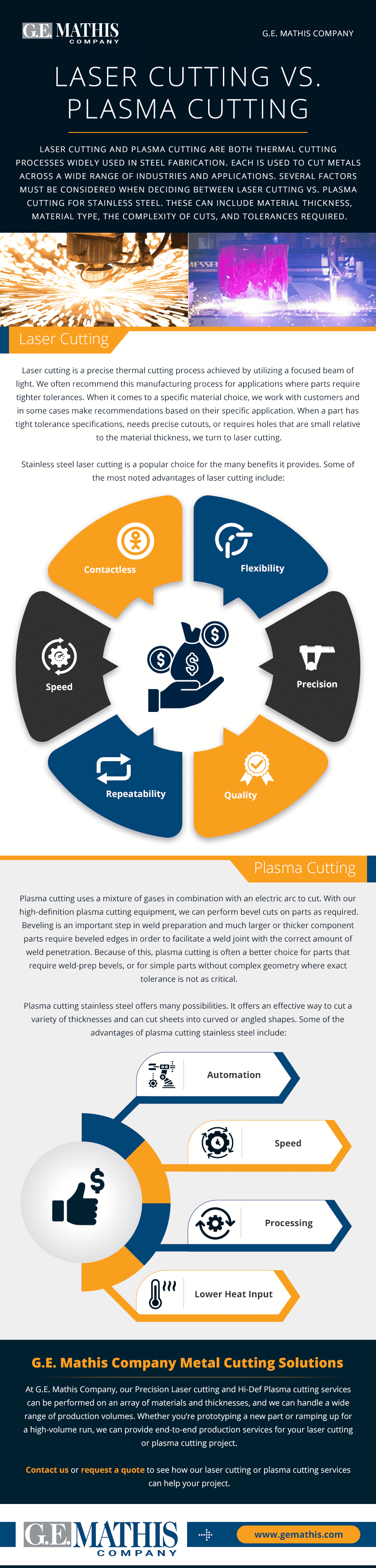

Laser cutting and Plasma cutting are both thermal cutting processes widely used in steel fabrication. Each is used to cut metals across a wide range of industries and applications. Several factors must be considered when deciding between laser cutting vs. plasma cutting for stainless steel. These can include material thickness, material type, the complexity of cuts, and tolerances required.

Each cutting solution has its advantages. Your manufacturer can help determine the best cutting solution for your application, but it is still important to understand the laser cutting and plasma cutting processes and understand the advantages each can provide to help inform your discussion.

Laser Cutting

Stainless steel laser cutting is a popular choice for the many benefits it provides. Some of the most noted advantages of laser cutting include:

- Flexibility. Once a laser is set up and configured for a specific material type and thickness, cuts can be easily repeated on multiple parts, sheets, and plates without the need to change out tools.

- Precision. With general cutting tolerances starting at +/- 0.015”, laser cutting is well suited for precise cuts.

- Quality. Laser cutting produces component parts with greater accuracy than other thermal cutting methods.

- Repeatability. The consistent tight tolerances achieved with laser cutting ensure high repeatability between parts.

- Speed. Laser cutting can be faster than other traditional mechanical cutting processes, especially when making complex or extremely precise cuts.

- Contactless. With laser cutting, there is no mechanical friction to cause wear on tools. Only the laser comes in contact with the material being cut.

Plasma Cutting

Plasma cutting stainless steel offers many possibilities. It offers an effective way to cut a variety of thicknesses and can cut sheets into curved or angled shapes. Some of the advantages of plasma cutting stainless steel include:

- Automation. As a CNC (computer numerical control) cutting process, plasma cutting mitigates the risk of human error over hand-held cutting methods.

- Speed. Plasma cutting cuts as much as five times faster than many comparable cutting methods. The process makes cuts rapidly while simultaneously vaporizing the cut material.

- Processing. Plasma cutting is an ideal method for quickly producing high-quality blanks for medium-to-high thickness Stainless Steel. This cutting method is also good for mild steels of low-to-medium thickness.

- Lower heat input. Plasma cutting can cut extremely hard metals, such as high-strength steel or abrasion-resistant steel, with a lower heat input than other cutting methods.

G.E. Mathis Company Metal Cutting Solutions

The advice listed here should be considered as general rules. At G.E. Mathis Company, we consider which process is best suited to cut each part on a case-by-case basis. We offer both Precision Laser cutting as well as Hi-Definition Plasma cutting options, and also have the experience to help advise you on which is better for your project or application.

At G.E. Mathis Company, our Precision Laser cutting and Hi-Def Plasma cutting services can be performed on an array of materials and thicknesses, and we can handle a wide range of production volumes. Whether you’re prototyping a new part or ramping up for a high-volume run, we can provide end-to-end production services for your laser cutting or plasma cutting project.

In addition to being an ISO 9001:2015-certified manufacturer, G.E. Mathis Company can provide the following services:

- PPAP (Production Part Approval Process) – All Levels

- FAIR (First Article Inspection Report)

- Capability Studies (Statistical Process Control)

- CMRT (Conflict Minerals Reporting Template)

Contact us or request a quote to see how our laser cutting or plasma cutting services can help your project.

All About Metal Fabrication

Metal fabrication refers to the process of cutting, shaping, or molding raw or semi-raw metal materials into an end product. Depending upon the type and grade of metal, as well as the desired end product, metal fabricators may employ a variety of techniques to manufacture cost-effective, high-quality components for a wide range of industrial applications.

Types of Metal Fabrication Processes

Some of the different metalworking methods metal fabricators employ include:

Cutting

- Sawing is the oldest method of producing straight cuts through metal materials.

- Laser cutting employs a high-powered, focused laser beam of light to cut through the metal materials.

- Waterjet cutting operations utilize a high-powered water stream to cut through different materials, including metal.

- Plasma Cutting uses a mixture of swirling gases to cut through metal.

- Shearing uses two large blades to cut through metal like a giant pair of scissors.

- CNC cutting uses a computer-controlled machine to make precise cuts through metal via a variety of metal cutting techniques (e.g., laser cutting, plasma cutting, etc.)

- Die cutting employs steel rule (flatbed die cutting) or cylindrical (rotary die cutting) dies to cut out precise metal shapes.

Forming/Bending

Unlike cutting, forming (or bending) doesn’t remove material from the metal work-piece. Instead, the process alters the work-piece with a machine such as a press brake, or by a hand-held method such as with a hammer, or die to fit the required specifications.

Welding

- Submerged arc welding (SAW): This welding method employs a continuous electrode to create an arc between the welding rod and the work-piece. The addition of a thick granular flux forms a shield that protects the weld zone from atmospheric contamination during operations.

- Shielded metal arc welding (SMAW): This welding method—also referred to as stick welding—uses a welding rod coated in flux that carriers a high-power electrical current. The coating breaks down during welding operations, forming a layer of slag and a gas shield that protects the weld as it cools.

- Gas metal arc welding (GMAW): This welding method—also known as MIG welding—relies on an adjustable and continuous solid wire electrode. During operations, the electric arc formed between the work-piece and the electrode heats and melts the base metals to form the weld.

- Gas tungsten arc welding (GTAW): This welding method—also called TIG welding—requires the use of a non-consumable tungsten electrode. It produces strong welds without fillers.

- Fluxed core arc welding (FCAW): This welding method is similar to GMAW welding, except it utilizes a tubular wire electrode filled with flux rather than a solid wire electrode. Self-shielded FCAW operations rely only on flux to protect the weld zone, while dual-shielded FCAW operations rely on both flux and an external shielding gas.

Stamping

Uses a top and bottom die molded into a custom 3-dimensional shape. When the metal is pressed between the two dies, it conforms to the desired shape. This process is used to make many complex metal shapes, such as body panels for the automotive industry.

Machining

Uses CNC-controlled machinery with various cutting tools to rapidly produce a custom 3-dimensional metal component by removing unwanted materials.

Advantages and Applications of Metal Fabrication Processes

There are several different types of metal fabrication processes employed by industry professionals to produce metal parts and products. As each process utilizes different techniques and equipment, it offers distinct advantages and best use cases.

Advantages and Applications of Cutting

Perhaps the most ubiquitous of all metal fabrication processes, cutting can be employed alongside other methods. In general, cutting offers several advantages with more modern techniques providing enhanced manufacturing capabilities. Some of the advantages of using cutting to fabricate metal parts include:

- Greater precision

- Higher repeatability

- Faster production speeds

- Better cost-effectiveness

Advantages and Applications of Forming/Bending

Metal fabricators use forming operations—e.g., rolling, indenting, and bending—to produce many metal parts, such as pipes, enclosures, and boxes. The advantages of using these operations include:

- Broader product capabilities

- Greater part design flexibility, including for complex shapes and geometries

Advantages and Applications of Welding

In general, welding allows for minimal waste production, reduced labor and material costs, and process portability. Each of the individual welding techniques also offers unique benefits. For example:

TIG Welding Benefits

Commonly used for aluminum and aluminum alloys, TIG welding produces a better surface finish than MIG welding and doesn’t require a filler material to produce the weld.

MIG Welding Benefits

Commonly used on steel, MIG welding does require the use of consumable filler material (i.e., the feeding wire). However, compared to TIG welding, it is faster and easier to control.

Sticking Welding Benefits

Commonly used on iron and steel, stick welding is the simplest welding technique. As such, it is used extensively for industrial fabrication applications.

Advantages and Applications of Stamping

Stamped parts are found across a diverse set of industries. The stamping process allows for:

- Higher precision and accuracy

- Faster production speeds

- Lower per-unit production costs (for high-volume runs)

Advantages and Applications of Machining

Machining is a broad industrial term for subtractive manufacturing processes, such as drilling, milling, and turning. While some companies still rely on manual machining units, many companies have adopted the use of computer numerical control (CNC) machining equipment. The latter enables industry professionals to achieve the following:

- Tighter tolerances

- Higher production consistency

- Greater cost-efficiency (for small to medium runs)

Metal Fabrication Solutions From G.E. Mathis Company

At G.E. Mathis Company, we offer industry-leading metal fabrication services to customers across a diverse set of industries. Equipped with a 135,000 square foot, state-of-the-art manufacturing facility and over a century of industry experience, our team provides:

Precision Laser Processing

Precision CNC Plasma Cutting

We utilize 4-axis machines capable of high-definition cutting action to provide precision CNC plasma cutting services. The equipment’s 400 amp, straight, dual-head, and contour beveling capabilities help us provide superior results across a wide variety of materials, including carbon, aluminum, stainless steel, and exotic metals.

Precision Forming/Bending

For our precision forming/bending operations, our team utilizes eight hydraulic press brakes, including two equipped with CNC capabilities. These machines feature 400- to 1,000-ton capacities and accommodate thicknesses up to 2 inches and lengths of 20, 20, 30, 23, 25, 40, and 48 feet.

Some of the formed/bent components we fabricate include:

- Cones

- Cylinders

- Ob-rounds

- Segments

- Channels and angles

- Bump formed sections

We process a variety of materials in these operations, such as:

- Carbon steel

- Stainless steel

- Aluminum

- Brass

- Bronze

- Copper

- Titanium

- Hardox® wear plate

Precision Welding

Our AWS-certified welders are capable of providing precision arc and MIG welding services using CNC-controlled welding and fully automated processes, including:

- Dual-wire submerged arc welding

- Flux cored arc welding—i.e., FCAW

- Gas metal arc welding—i.e., GMAW

- Gas tungsten arc welding—i.e., GTAW

- Shielded metal arc welding—i.e., SMAW

- Submerged arc welding—i.e., SAW

We weld materials up to 12 feet wide and 50 feet long, including:

- Carbon steel

- Stainless steel

- Aluminum

- Hardox® wear plate

HARDOX® Wearparts Fabrication

- HARDOX 450

- HARDOX 500

- STRENX 100 (Domex® 100)

- STRENX 110 (Domex® 110)

- STRENX 700

- WELDOX 100

- WELDOX 110

These products are available in up to 2-inch thicknesses with industry-leading tolerances to meet even the most demanding application requirements.

In addition to being an ISO 9001:2015-certified manufacturer, G.E. Mathis Company can provide the following services:

- PPAP (Production Part Approval Process) – All Levels

- FAIR (First Article Inspection Report)

- Capability Studies (Statistical Process Control)

- CMRT (Conflict Minerals Reporting Template)

At G.E. Mathis Company, we have over a century of experience providing metal fabrication solutions. If you have a metal fabrication project, we can meet your needs. Contact us today for more information about our metal fabrication capabilities or request a quote from one of our experts for your next project.

Announcing the Addition of the 8-kW Fiber Optic Laser Cutting System

As an industry leader in the fabrication of long, close-tolerance components, G.E. Mathis Company is committed to continuously expanding its service offerings. Most recently, we’ve added an 8-kilowatt fiber-optic laser cutting system—one of the largest pallet-changing laser formats in the industry—to our facility. This new addition allows us to increase the efficiency of our processing operations for materials as large as 100 inches wide by 240 inches long as well as offers several other improvements to our laser processing capabilities.

Features and Capabilities of the 8kW Fiber Optic Laser Cutting System

The integration of the new 8kW laser into our facility has greatly increased and improved our laser processing capabilities. Employing a 3-axis flying optic (or hybrid) positioning system, LoadMaster automatic sheet loading system, and BrightLine Fiber adaptive laser beam in a full enclosure, it accommodates the following project specifications:

- Manufacturing type: prototype, contract manufacturing, and fabrication

- Materials: carbon steel, stainless steel, abrasion-resistant (AR) steel such as HARDOX®, high-strength steel such as STRENX®, aluminum, and other alloys.

- Material thicknesses: up to 1.25 inches for carbon steel and up to 1 inch for stainless steel

- Tolerances: starting at +/- .015 inches

- Volume: Prototype to production

- Delivery/lead time: 1 to 2 weeks

- Industry standards: 1SO 9001:2015

- File formats: AutoCad, Inventor, PDF, DWG, DXF, STEP

Benefits of the 8-kW Fiber Optic Laser Cutting System

Using the new system for our laser processing operations provides us with a number of benefits, including:

- Broader material capabilities. The laser system allows us to cut a variety of steel and steel alloys in greater thicknesses (up to 1 inch for stainless and 1.25 inch for carbon).

- Higher cut quality. The system’s BrightLine Fiber adaptive beam mode facilitates the production of higher quality cuts in even thick plates, simplifies the removal of individual parts, and reduces the contours created throughout cutting operations.

- Safer and more environmentally sound operations. As the system’s critical components are fully contained within an enclosure, laser processing operations that employ it offer a lower risk to personnel and the surrounding environment.

Industries Served by the 8kW Fiber Optic Laser Cutting System

Equipped with the new system, we are able to provide more advanced laser processing services to the following industries:

- Aerospace

- Agricultural

- Contract manufacturing

- High-quality component manufacturing

- Military

- Construction

- Mining

Laser Processing Solutions From G.E. Mathis Company

At G.E. Mathis Company, we are dedicated to providing high-quality laser processing solutions to our customers. Craig Mathis—President of G.E. Mathis Company—best states how we go about achieving this goal: “We continue to invest in the latest fabrication technology which enables us to deliver value-added products to the industries we serve.” Our current processing equipment includes three different types of lasers (including the 8kW fiber optic laser) and large-capacity gantry-type and pallet-type processing systems, which allow us to cut a wide range of designs and geometries in materials ranging from 16 gauge sheet to 1.25 inch thick plate.

In addition to being an ISO 9001:2015-certified manufacturer, G.E. Mathis Company can provide the following services:

- PPAP (Production Part Approval Process) – All Levels

- FAIR (First Article Inspection Report)

- Capability Studies (Statistical Process Control)

- CMRT (Conflict Minerals Reporting Template)

In addition to our top-of-the-line laser processing services, we also offer secondary and finishing services. As a one-stop shop, we provide faster turnaround and reduced manufacturing costs. For more information on our laser cutting equipment and services, contact us today.

Laser Types & Configurations for Cutting Sheet and Plate Metal

LASER is an acronym that stands for “Light Amplification by Stimulated Emission of Radiation.” Laser cutting is a thermal process that utilizes a focused and amplified beam of light to cut material into a variety of shapes with great precision. The thermal intensity produced by the laser beam melts material in the area of focus, while a mixture of gases forced through the torch tip of the machine eject the molten metal, creating a kerf. By moving either the laser beam or the material being cut under Computer Numerical Control (CNC), the operator creates a continuous cut on the material.

An examination of the various types and configurations of lasers used for sheet and plate metal cutting, and the advantages of the laser cutting process over plasma, oxy-fuel, and other metal cutting techniques helps illustrate the importance of lasers in metal fabrication.

Types of Lasers for Metal Cutting

CO2 Laser

The first type of laser used in cutting sheet metal, the CO2 laser generates a beam of energy within a mixture of carbon dioxide, helium, and nitrogen gas. This type of laser is capable of cutting thicker materials at higher speeds than other laser types, such as fiber lasers, and produces less of a micro-burr along the cut edges.

It is available with different beam movement configurations—which relate to the different methods of CNC movement required to create a continuous cut. The configurations available include:

Flying Optics System

This configuration is the most popular. The Flying Optics system fixes the workpiece in place, while the mirrors (or other optical components) are manipulated along the X- and Y-axes. It offers two advantages over other control systems, including:

- Easier prediction and control as the motors are always moving a fixed mass with no variation

- No limit to material weight since the workpiece does not need to move

Despite these advantages, flying optics systems have an issue with variations in beam size. Because a laser beam is never perfectly parallel and slightly diverges as it leaves the laser, slight variations in cutting performance may occur as the beam moves over different areas of the workpiece.

Fixed Optics System

Rather than moving the optical components, a fixed optics system moves the workpiece table along the X- and Y-axes, while the laser optics remain stationary. Whereas this approach overcomes the beam divergence issue, it is not an ideal mechanical design; for lighter sheets, a fixed optics system may work well, but, as weight increases, accurate positioning of the material at high speed decreases.

Hybrid System

The development of a hybrid system was an attempt to combine the advantages of a flying optics system and a fixed optics system. In a hybrid system, the optical components move along one axis while the workpiece moves along the other. While this design improves on some of the disadvantages of the other two configurations, it does not resolve the limitation on workpiece weight. Additionally, its more complex setup causes more issues in coordination between the two components.

Advantages of CO2 Lasers

- Capacity to cut thicker material at the same or lower wattage of a fiber laser

- Less micro-burr along cut edges when cutting thicker metals

Fiber Laser

Unlike CO2 lasers, fiber lasers do not use mirrors within the light-generating source. Instead, they generate a beam using a series of laser diodes. The generated beam then undergoes amplification through an optical fiber, similar to the laser cavity in a CO2 laser. Collimation, which limits divergence, takes place as the amplified beam exits the optical fiber, followed by focusing through a lens or a concave to focus the beam on the workpiece for cutting.

Advantages of Fiber Lasers

Some advantages provided by fiber lasers over CO2 lasers include:

- No requirement for gas circulation

- Reduced maintenance requirements and costs of operation (no fans and no mirrors)

- 2–3 times more energy efficient than CO2

- Cuts thinner metals faster due to better wavelength absorption at the cutting surface

- No risk of back reflections from reflective metals (e.g., copper, brass, aluminum, etc.)

Direct Diode Laser

The most advanced technology among solid-state lasers is the direct diode laser. These lasers make use of several beams produces from laser emitting diodes of varying wavelengths, which are then superimposed into a single beam for cutting using beam combining techniques.

Advantages of Direct Diode Lasers

Overall Advantages to Laser Cutting Over Conventional Cutting Methods

When cutting sheet metal laser cutting offers several advantages over other cutting methods, including:

- Limited to no contact during cutting

- Less power consumption

- Increased safety over hand-held methods

- Increased versatility on types of metal that can be cut

- Suitability for multiple types of metal with a single laser machine

- Much higher cutting precision and tighter tolerances than plasma cutting

Conclusion

At G.E. Mathis Company, we have large-capacity laser processing systems, including gantry-type and pallet-type equipment. Our gantry system can process metal up to 14 feet wide and 100 feet long, while our pallet equipment processes sheets and plates up to 8 feet wide and 20 feet long. Both systems are capable of producing maximum power outputs of 8,000 watts. Our CO2 and fiber lasers produce high-quality components using metal ranging in thicknesses from 16 gauge sheet up to 1.25 inch plate. With our advanced laser equipment, and the expertise of our team, we can cut nearly any shape with precision and accuracy.

In addition to being an ISO 9001:2015-certified manufacturer, G.E. Mathis Company can provide the following services:

- PPAP (Production Part Approval Process) – All Levels

- FAIR (First Article Inspection Report)

- Capability Studies (Statistical Process Control)

- CMRT (Conflict Minerals Reporting Template)

For additional information regarding our sheet metal laser cutting capabilities, visit our laser processing page. To find out how we can help contribute to the success of your next project, contact us, or request a quote from one of our expert team members.

Laser Cutting Vs. Plasma Cutting

“Should I use laser cutting or should I use plasma cutting?”—that is the question. Certainly for manufacturers like us, this is a question we receive from many customers; what is the difference between the two and which cutting process is better suited for their end application? While the answer is not cut and dry, there are some general rules that separate the two processes.

For parts that have simple shapes, without many cutouts or intricate notching, we typically utilize plasma cutting. When a part has tight tolerance specifications, needs a precise cut, and/or calls for a small hole diameter in relation to the thickness of the material, then we utilize laser cutting. Again, these are general rules and we consider which process is best suited to cut each part on a case by case basis.

Now, hopefully you have a better understanding of whether laser cutting or plasma cutting is better suited for your application. If not, let us help determine the right cutting process for your parts!

For more information, feel free to contact us today or request a quote for your next project.

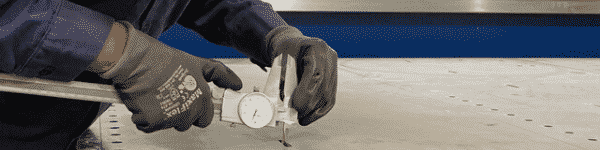

Constructing your Stainless Steel Needs

For one customer in particular, they came to GE Mathis Company. This customer came to us with an engineered drawing of these exact needs. So how did we fulfill their requirements? We took A240-T304 stainless steel and used our 6,000 watt laser to cut the stainless steel plates precisely to the customer’s specifications. Once the panels were cut, we then ground and de-burred the laser cut edges to ensure that the panels were precise and ready to use. Even better – we were able to do all of this in three weeks! It is important to our entire staff to meet the needs of every customer – whether in the architectural field or other industrial fields.